I am attempting to print round spacers for a project using PLA from Snapmaker and Hatchbox. They are ~12mm round, 12mm tall, so all the movement is pretty well focused and contained to a small area of the bed.

The prints are completing successfully, though I am running into a wall, having ran through nearly 12x 1h prints and they each have the same two issues.

-

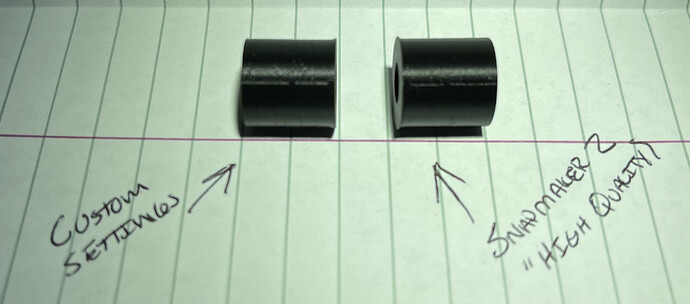

Horizontally, decreasing layer height results in line visibility decreasing at the expense of increased time to complete, though throughout the print there are either several empty “dots” (about the size of a dead pixel) or extended horizontal lines about 2-3mm – both appear empty about 1-2 layers deep.

-

There is a divided vertical line split only by a small filled gap on the back of every print – almost as if the print is being marked at the 50% mark. Watching the print from the back, the position of the line is exactly where the extruder stops before it continues the print. I don’t understand why between the end of the first line and the next, 4-6 layers fill without any issues.

What I’ve Done

-

Calibrated the bed. I first heated the nozzle to 205 and the bed to 80, quickly tightened down the screws for the frame, and then brought the nozzle down to a 0.05 gap. Originally, I tried zeroing fully, however, the first print resulted in dragging on one side of the print be, so I brought it up a bit.

-

Checked the consistency for the PLA from Snapmaker and Hatchbox using a micrometer – all in range for their tolerances. The Snapmaker filament is Black, the Hatchbox is glow in the dark.

-

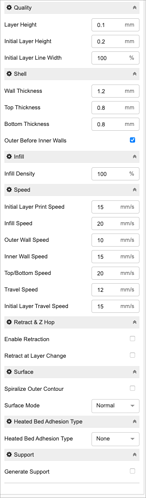

Tested Snapmaker recommendations for Fast Print, Normal, and High Quality before moving on to my own settings to further reduce layer size and speeds, reduce print temperature from 200-205 to 190-195 (see attachment for the settings of the last run).

-

Tried printing outer walls before inner walls – this doesn’t seem to make a difference. Increasing or decreasing the wall or top/bottom thickness doesn’t seem to help either.

-

Checked for wobble in the bed – it’s solid and there’s no visible movement during the print, and it would take a good bit of force to make it wobble by hand.

-

The printer unit is tightened down well; no movement during prints or when pushing on it.

Any ideas on what I am doing wrong, or where I can improve to remove the vertical lines and further reduce or remove the horizontal gaps?