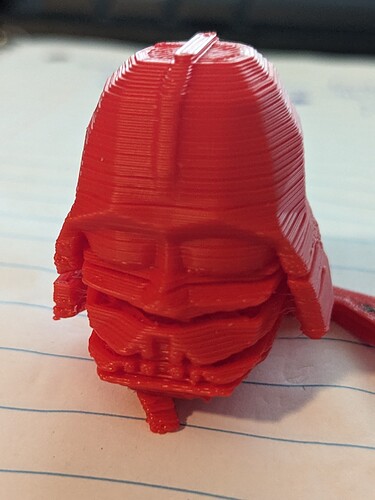

My Vader print is missing some layers not Shure why ? Thanks

Need MANY more details.

What machine?

What filament brand & type?

What slicer settings?

What calibrations have been done?

Snapmaker 2.0/350

Inland red PLA 190-210c

Slicer ? looking into that definition, sorry

All calibration on the home screen completed in order.

Thanks a ton.

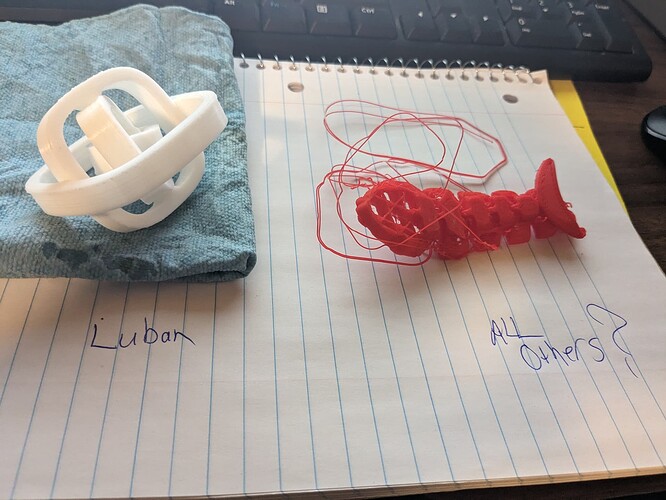

Slicer = LUBAN

Hi THXRWP, Not sure how long you’ve had your A350, I’ve had mine for a year now, also using Luban. I have seen this sort of behaviour, but the reasons might not be the same. After about 5kg of mixing PLA with PETG in the same hot end the 0.4mm nozzle developed a clog. Perhaps I was running it too hot? When I stripped the hotend down I found the teflon sleeve appeared burned out. It is possible to replace the teflon, with average success. A new hot end fixed it for me. Also, looking at your print, the layer height seems very large (or that could be as a result of the problem) I’m guessing 0.4mm for extra speed? I try to keep my layers about 0.2mm for rough drafts. I found the cube pattern useful for tinkering with the settings. Finally I had to calibrate the extruder (e-steps) a must if you haven’t done that already.

Ya, curious to see the slicer settings as well. I’m guessing a very large layer height.

layer height: .16

speed: 50mm/s

model structure :medium

support : none

adhesion type: skirt

Note: my 1st print (this was my 2nd) was a cube that turned out nice.

Well those parameters seem reasonable… this is somewhat daft but, try the cube again and see how it turns out, then try Jeff Vader again (you have to be an Eddie Izzard fan). I notice your settings have no support and a fairly high print speed, that might cause unusual behaviour for a model with these sort of overhangs? Add support and slow it down - see what happens. Learning to drive these printers is half the fun/frustration* delete as appropriate ![]() I’ll check back tomorrow :

I’ll check back tomorrow :

thanks man, was printing the cube already right now and had to stop it ,looks like its just pouring out red, getting piled up all over the nozzle and then the project. Could red be bad ? white was fine, or did i screw up my first unload/load seemed pretty easy ???

UR welcome, it’s possible the heat required for red PLA is lower, or the extrusion settings are corrupt/incorrect in Luban. I notice each material has a separate profile for colour too… Was the white filament also PLA or PETG. That runs quite a bit hotter and PLA would not respond well at that temperature. I think that was my mistake and I ended up “burning” residue PLA in the nozzle with PETG temperatures.

Hey, it seems like you are new to 3D printing and the Snapmaker, can I recommend, when and where you have time, you have a read of this forum post: 3d Print Guide_Walk Through - Snapmaker 2.0 / Getting Started - Snapmaker: where creation happens.

There are a lot of useful guides on there including calibrating your E-steps (something not provided on the Snapmaker’s touch pad as a calibration but is critical to getting good quality prints), and may be part of your issues experienced here.

In terms of your print, I am not noticing any strining but it does also appear like you are having some heat issues, so not sure what temperature you are currently printing at, this is changed in the filament settings in the top right hand corner, not in the machine settings. Should you wish you can go as far as doing a temperature calibration tower to determine the best temperature for the filament.

Make sure your filament spool spins freely so it can feed the extruder as easy as possible.

BINGO ! thanks

Sorry for the delayed reply but have have had lots of issues in 3d printing and life lately. However I have found that the filament spool was binding and that I can print successfully from the Luban 3d print files but if I import/download from anywhere else I get a bad(fuzzy)first few layers, and a massive core shift about 30 to 50 % into a print, almost like it skips a few layers.

This is not the same model isn’t it?

What are the other methods you transfer or print with?

I am wondering, thought your case is closed?

RESOLVED : thanks everyone for all the help. I found 2 issues ,1minor 1 major.

- Filament spool binding was a slight problem on occasion.

- Major intermittent problem was a loose cable.