My 10mw laser that I ordered on March 8th finally got delivered earlier today and after reading this I’m debating even using it versus just selling it and getting a dedicated laser engraver. Luckily I have another 2.5 days of a super long print that is is currently printing so I have time to decide. Any updates on the 10mw laser from people that have had theirs for awhile?

I’ve had it for awhile now, and I’ve put the 1.6W back in once for a comparison test. That’s it. My A350 has pretty much stayed setup with the 10W since it arrived and after my initial tests. My latest test has been pushing it way beyond what they advertise (I tried to cut 19mm solid maple hardwood, it got through 14mm!) Which they advertise as max 8mm in soft basswood.

Now that I’ve dialed in my linear rail’s backlash (I never bothered as none of the other projects I was working on allowed me to notice the error) the horizontal mismatch is gone. I agree with Skreelink that this thing way outperforms the advertised capabilities as far as what kinds of things you can do with it. I was hearing the proper setting for black anodized aluminum was 200mm/min at 100%. I was running it at 1000mm/min at 100% and still getting good lines (movement induced problems aside). If anything I find myself dialing back the default settings, as when I wanted to make a line on soft wood the default profile for basswood really LEFT A LINE if you know what I mean.

With the 1.6w I feel like I was always running things slow enough that the kinds of problems I’m seeing were so minor that I never noticed them, and sure I could just set the 10w down to like 10% and leave the speeds low, but I’m really enjoying tuning my machine to be able to CRANK out high quality stuff. I’m gonna need it, I might be looking at a massive order coming in, which is both exciting and terrifying.

I sincerely planned not to write a “mine arrived, I’m impressed”-post. But I can’t stop myself, because I am impressed! It arrived today (ordered Jan 25), and I had not much time, so I tried 9 mm poplar which I could not get through with the 1.6 W laser - 2 passes with 10W and done (1 pass was just not enough). Next test 14 mm massive oak - 5 passes, 1 mm stepdown: 90% through, I guess one or two more passes and I would have nailed it (However, the cut is really scorched). A bit of rusty steel: clearly marked in one pass. It is really a considerable update! I like! Btw.: All at 100%/140 mm/min.

But, man, I’m glad I have the goggles… Wisely ordered an extra pair, so my wife could watch with me ![]()

Get anywhere with mirrors? Mine arrived Friday and I was curious about just using a sheet of wet paper on top… or am I mad?

-EDIT- I’m mad, or at least unsuccessful trying a very wet mirror with cigarette paper on top. I then flipped the mirror over and used the anodized aluminium settings (350mm/min) and it easily removed the reflective layer and micro-cracking around the path engraved, so 100% was overkill. Still haven’t tried the sharpie yet.

Most people who do mirrors do the back.

Too much chance of either harming your machine or yourself if you try to engrave on the front.

-S

Most people who do mirrors do the back.

Too much chance of either harming your machine or yourself if you try to engrave on the front.

This is a really good safety point for anyone,

lasers are not something to be casually played around with!

You are correct about driving twice with 80% power. Had a similar issue with 5mm bass wood. I would say it cut 4.8mm deep and did not go cleanly thru on the 1st pass.

So I finally got my laser last week and got it installed tonight. I’ll be perfectly honest. I’m impressed. I did the auto calibration and threw some settings into the machine and hit go. I have no idea what settings I used because I was in a hurry. It did a great job for my media. I tried this with the 1.6 and got zero result. It’s an odd thing to laser engrave so I’m sure the judgement will roll in. In smelled terrible too but it turned out amazing.

Take note of the post from @Hauke!

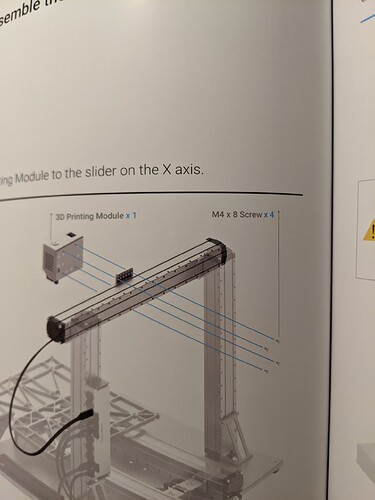

Installed the 10W laser yesterday and couldn’t work out why it kept stopping complaining about overheating. Looked today and sure enough I had used the M4x10 screws used by the other heads. Installed the M4x8 that came with the 10W laser and no overheating problems. Problem is the fan is a bit rooted now and has a really high pitch squeal coming from it.

There is absolutely no warning on the head or the manual that you must use the screws that come with the head.

This is pity piss weak not warning us.

People always blame others for their inability to follow directions… In the original snapmaker assembly manual, it says to use M4x8 on the toolhead, and again in the 10W manual. Why do so many people use the M4x10?

From my old A350 manual:

M4x10 use is user assembly error.

Thought all the heads were installed with M4x8? I just reused the screws on my 3D print head.

You bring the tortillas and I’ll bring the beef and we’ll have a taco party!

I had to rethink my plan because after cooking the engraved meat you could no longer see the engraving. I still think it turned out really good.

That flagstone’s come out really nicely. What’s 100% workspeed mean? I assume you mean on the touchscreen it’s set to 100% power and speed, but when you generated the gcode in Luban/Lightburn what speed (mm/min) or material engraving profile did you use? If you still have the gcode file it mentions feedrate for example F1500 at the end of some of the gcode instruction lines, as a last resort ![]()

Have you tried cutting the steak with the laser

No, I’m sure it would go through a thin piece though. I just wanted the logo burned in. It performed well but stunk like you wouldn’t believe. My wife has forbidden me from engraving anything that once had a face after stinking the entire house up with the brisket.

white ceramic tile, mirror (from the back), and MDF from the sample pack. Obviously, need a lot more testing with wood.

Does anyone have a list of settings for the 10watt and various materials?

Odd that it stunk. I would have assumed it would just smell like a BBQ or grilling.