I haven’t had the module long (a few hours, not long enough to formulate a real review or anything) but there’s a few things that stick out to be annoying, but at the same time, it lives up to the ‘massive power upgrade’ claim.

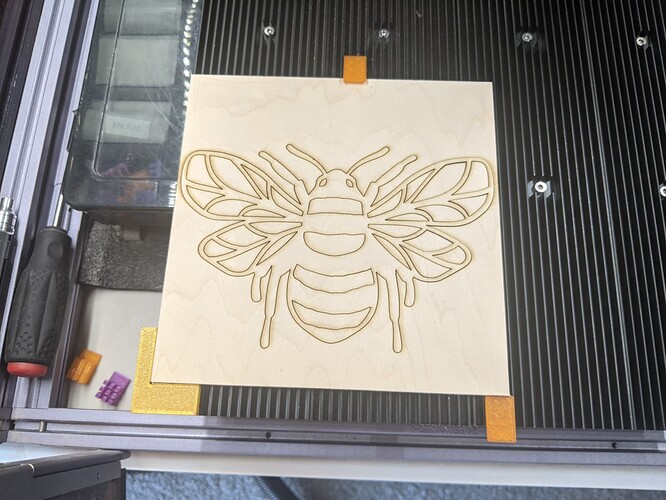

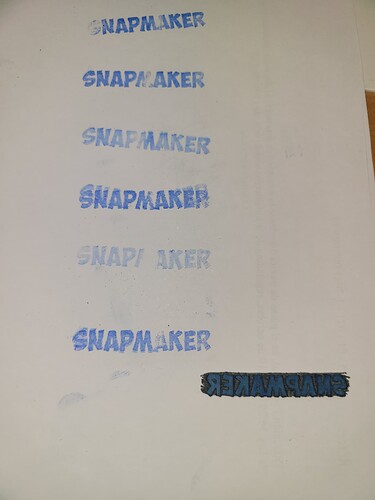

First off; the very first test.

Material; 5mm Maple plywood, poplar core.

Using the default 5mm settings in Luban 4, one pass, took 14 minutes. I’ll note to put lifters under it to keep sticky smoke residue off my plate in the future, but impressive results. So the power upgrade is definitely there.

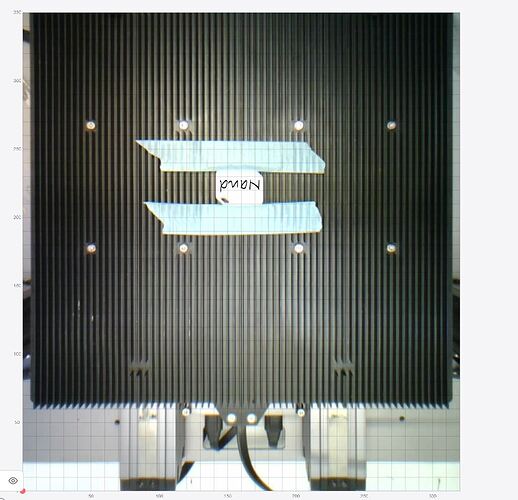

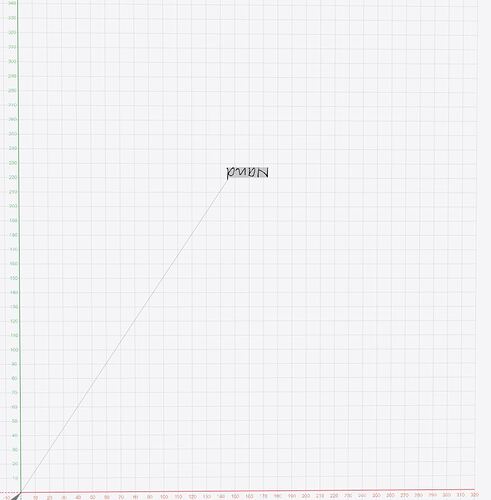

Next came setting up for the new true origin… this is where things go a little mank. Apparently Luban has a problem with origin mode. The bee was done with the image capture, worked great. However, trying origin mode it seemed a bit random as to where it actually started. Even manually adding in G53 and loading it back into Luban, it was… way off. Something like ~30mm difference from sending the file to the snapmaker and running it locally. Maybe a restart would have helped? I don’t know. Moving on.

I made a 10x10 square, set 10mm from X/Y, G53’d the gcode and ended up with X4.5 Y19, so my new true origin is X5.5Y-9 (change from my 1.6W module X2Y-15). Work speed was 3000, still cut deep, surprisingly. During this test I found out another really annoying thing about the new auto focus (which is nice and accurate it seems comma but)…

It FORCES centering your object if you run it locally on the machine. In Luban, clicking auto mode will move the toolhead over the object in the corner in my test, but running on the machine it centers the toolhead and just says “place the object in the center of the platform” with no options to move the toolhead. So if you’re using an origin method not centered, unless you have a large object, you can’t use the new fancy auto thickness measurement.

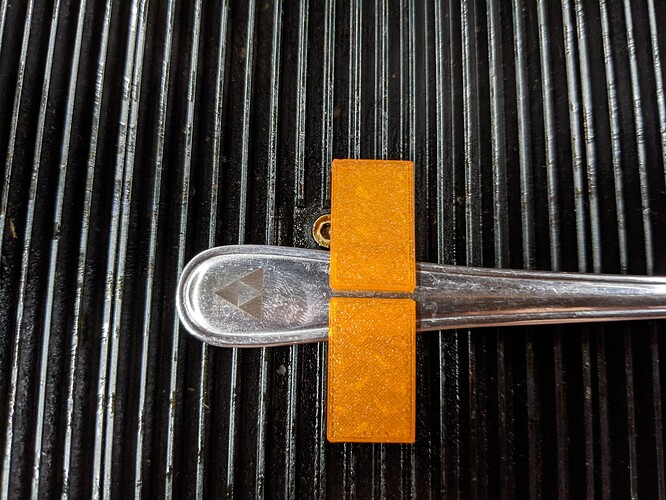

The manual method touches down using the calibration card, no option to manually input the thickness locally. However, if you run it in Luban, manual mode just asks for the thickness (like 1.6W “auto” mode). Hopefully Snapmaker lets us move the toolhead over our object instead of moving our object under the toolhead before measuring thickness in the future.

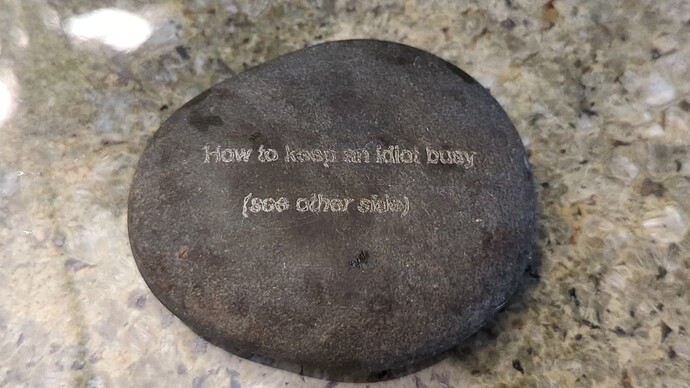

I’ll update this thread with more impressions and information as I do more tests, feel free to put your experiences in this thread too! My next test will be anodized aluminum and then I’ll see if I can come up with some stainless to test… Maybe I’ll personalize a spoon…