Hi everyone,

We’re excited to share the first part of Michael Winkler’s CNC Academy series, focusing on aluminum milling with the Snapmaker Artisan. Michael is an experienced Artisan user, and he’s put the machine to the test to explore what’s possible in desktop CNC.

![]() Why this is worth reading

Why this is worth reading

-

Material choice matters: Michael recommends 6026LF aluminum for clean chips and smooth surfaces. 6061-T6 works as a backup, while unknown or cast aluminum can cause problems

-

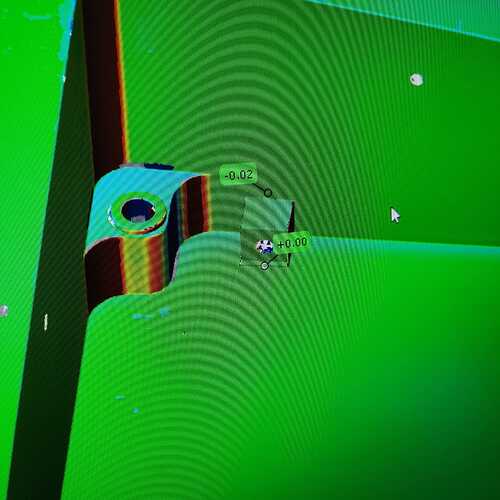

Machine tips: The Artisan can achieve precise dry milling when used within its limits. High spindle speed, rigid frame, and careful setup are key

-

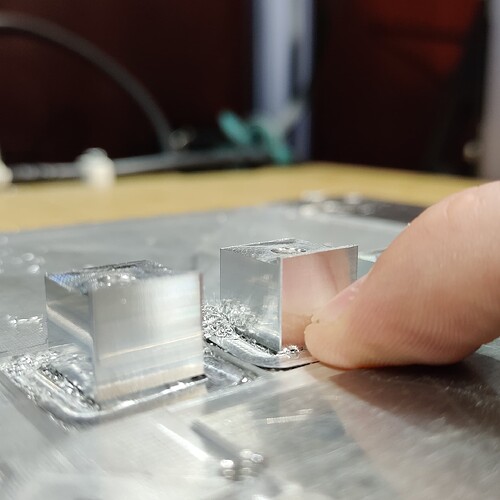

Workholding and strategy: Stable clamps, subplates, proper alignment, low chip load, and conservative feeds make all the difference

Michael’s guide isn’t just about results. It’s about learning through experimentation, understanding your machine, and building skills safely. Future parts will cover more materials, fixtures, and workflow tips.

![]() Read the full article here The Artisan CNC Series – Part 1

Read the full article here The Artisan CNC Series – Part 1

https://blog.snapmaker.com/blog/the-artisan-cnc-series/

What CNC projects have you tried with your Artisan? Share your experience and tips in the comments so we can learn and grow together!