Trying to reliably get through some ~3mm plywood and was having issues. I was cutting 10 passes at 95mm/min and wasn’t getting through my entire cut. So I set out to investigate.

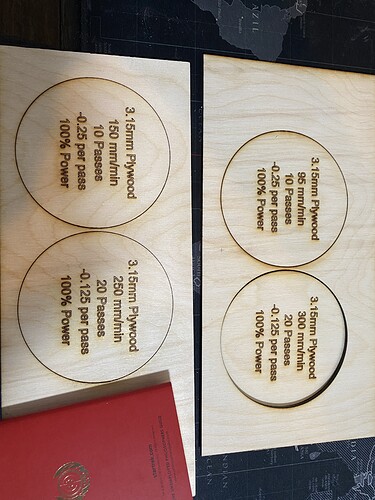

First attempt was 95mm/min @ 10 passes and 300mm/min @ 20 passes.

Second attempt was 150 mm/min @ 10 passes and 250mm/min @ 20 passes

You can see that neither options cut through entirely, though there was some telling information from these cuts.

In the above photo the bottom left is the 95mm/min and the top left is 150mm/min. The cuts with the faster work speed are finer than the slower ones, and on the 95mm we can see heat/smoke staining on the edge, which is reduced at 150mm/min. There is none visible at 300mm/min and 250mm/min.

This morning I did another set of cuts to test it out. One at 150mm/min @ 15 Passes and 200mm/min at 15 passes. (Apologies for not updating the text on the cut outs to reflect these changes).

This is the most complete cut I have so far, and as you can minimum heat/smoke staining on the underside.

As you can see with these tests I’ve found 150mm @ 15 passes to be optimal. But the question is why did the faster speeds cut better than the slowest speed? My first thought was that slower should cut deeper. However it would appear to be a point of diminishing returns there, and my thought is that it is caused by smoke.

With the cutting speed moving so slowly the laser is spending more time on a given spot. This heats up the cut material as well as the surrounding material to a higher level (as evidenced by the staining and wider kerf) generating more smoke that refracts or obstructs the laser beam reducing its effectiveness.

By using a higher speed less heat and smoke is generated in the kerf allowing the laser’s beam to hit the material consistently.