@Rwide 2mm this time

Can you please translate this?

So for example, if you’re printing with 0.2mm layers at 60mm/s you would do: 0.4x0.2x60 = 4.8mm 3/s. This is a speed that a properly functioning.

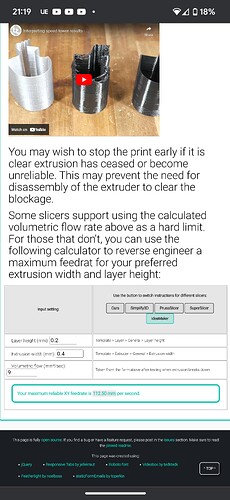

So my nozzle is 0.4, I want to print at 60 mm/s… now where to I check if the 4.8 is correct?

Normally from what I’ve read the snapmaker 2.0 single extruder has about 9mm3/s… Unless I’m mistaken…

It looks terrible… I would turn retraction off and print the same thing again. Or just enough of it to diagnoze…

Does snapmaker has a setting where I can check the advance pressure in nozzle?

Maybe it’s something my printer doesn’t have tunned

Yea the cubic calculation looks right to me. But the slicer does that calculation for you so there is no need to bother with that unless you want to go much faster than you are…

If everything works like it should with your machine, 60 mm/s with a 0.4 nozzle shouldnt be a problem.

Not sure what you mean, but if you’re reffering to the k-factor, it should be saved in the eeprom i think. There is probably a marlin command for it…

There it is: Linear Advance Factor | Marlin Firmware

Ah no… k factor at 0.04… been at 0.07… never made a difference…

With the risk of looking stupid… But I’ve never put thermal paste when changing the hot end… is that mandatory?

Just thinking it’s something happening from the moment the filament enters the hot end…

@Marius87bv I think you should disable retraction and see what happens ![]()

@Marius87bv Yes it matters. Sometimes it works without it but it will always work better with it.

Maybe you have heat creap issues because the heat is not trannsferred properly from the heat break to the cooling block… This can cause temporary clogging. Frequent retractions at high length will make this type of problem worse…

So I guess that’s next… thermal paste… Time to Google that now… how much and where :)))

Started the print with no retraction… I guess you are right… it does look like a temporary clog… and then it sorts itself out

@Marius87bv Seems like some type of blockage. I would probably dissassemble the hotend at this point… Maybe 250 e-steps was too much?

Don’t know anymore… the part seems alright in places

What would you suggest to do if I cake out the hot end?

Inspect the filament pathway and make sure there is no blockage. Could be a piece of broken filament or previously melted/softened plastic somewhere. However there are other things you can try first if you want to avoid dissasambling the hotend/toolhead.

- make sure your z kinematics are ok. Do this by printing an object 2 times with the same settings and placement, but with different speeds. Then compare the objects to see if the horizontal lines match. Id they do match, your z kinematics could be the issue…

- you could try a few “cold pulls”

- you could try unclogging through the nozzle with an acupuncture needle.

Ah yes, so I have changed the hot end just before starting this tread… Just to eliminate the clog suspicion… The previous hot eng was new as well but took it out just for me to see how it actually looks inside…

The ptfe inside as new… The inside of nozzle full off melted filament… no leaks…

Will print a couple of calibration cubes…

Just thinking that on lower layer height these issues disappear… Or not noticeable…

Maybe I need to change line width from 0.4 to something different… just not sure on the ratio

@Rwide what speeds you recommend?

I went to Cura, and sliced on each profile ( high, normal and fast ) changed only the layer height…

Really curious now

@Marius87bv Not sure. I’m not that familiar with your model. I have the J1 printer. Maybe you can start with 30 mm / sec and when you are satisfied with the results, you can go faster…

Just made 3 cubes… 60, 50 and 40… as expected in " tests" all good…

But in all honesty I have played with the speed from the the printer screen… it happens at any speed…

Must be my tool head… Can’t see what I need to change/repair to get to do decent prints…

The problem is that the @Snapmaker-Support not having the opportunity to actually see the machine… it’s hard to diagnose from the photos I send them

I certainly believe that is not a setting anymore… As everything is stock… Filament is definitely a variable… But I’ve used about 30kg until now, all different brands… And similar results…

If it’s not one thing is another…

Under extrusion on long travels

And then not sure what this is

Seam supposed to be straight

On the inside it’s straight

Maybe it supposed to be in the same place?

Not sure what the printer tried to do here

Looks like it tries to do a knitting job… layers on top and under others…

@Marius87bv seam looks normal to me. You can see where the seam is placed in the slicer preview before you print. Are you sure your part cooling fan is working?