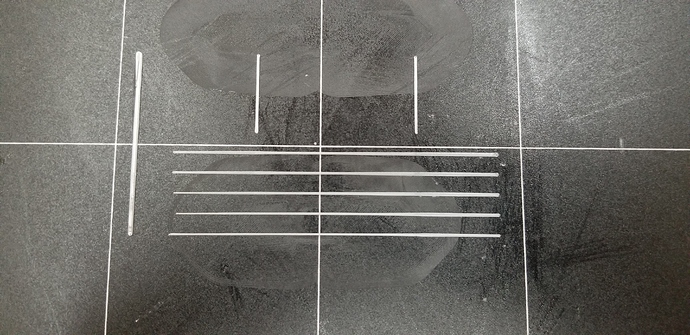

Shown in the image below the same lines but all printed using the same M900 K value (0.08). This was done by manually setting the M900 K value through the console in Luban and printing over a USB connection from a PC.

As you can see, the printed line quality shown is much different to the K0.08 line shown in the image from my previous post which suggests that the K900 command in the g-code file used to print the previous test was ignored.

Please can this be investigated properly as solving this issue would make tuning printer settings for different materials far less hassle as at the moment it requires manual changing through the console and re-printing per M900 K value tested.

2 Likes

Hey @C.Harris thank you for your testing.

You could write the M900 in your start-skript using cura, simplify3d for example.

I don´t know if luban could do so.

The point of this script is to dial in the M900 value though so putting a single value in the start script wouldnt help unfortunately. Im not even entirely certain putting it in the start script would do anything as it seems to ignore all the other M900 commands as well.

The only time M900 seems to work is when entering it into the console over a wired connection and saving it to the printer settings using M500.

I’m willing to bet that the script will work from Octoprint by bypassing the touchscreen. The touchscreen seems to have a few issues when it parses the gcode files. I will try to run the script tomorrow and let you know.

2 Likes

Thanks, that will go a long way towards narrowing down the cause of this issue!

1 Like

Does snapmaker team can answer about this bug ?

You never give exact answer about the bugs can you please be more involved. You guys only answer 1/5 questions on this forum.

We want snapmaker team to be more involved

2 Likes

Sorry I’ve been off for a while.

What’s the issue here? Are we still on the issue of M900 not working if it’s in the start script?

Thank you for revisiting this.

The issue is as posted above that M900 Kx.xx commands within a g-code file do nothing. This is evidenced by the images I posted on March 8th.

1 Like

@parachvte Has there been any progress on this?

you’ve probably solved it but you can print the K value test over usb-serial connection, this way it will respond. i’ve found any K value between 0.05 and 0.08 to be really good

I agree. I’m at 0.08 myself.

Yeah I gave him a tutorial over forum message for K value calibration

1 Like

0.08 is exactly what I set mine to as well!

Can we please get some response from the SM team, even just to say you are looking into this issue? The last meaningful input from an SM employee was Feb 27th, since then @parachvte had asked me to reiterate the issue which I did on the same day (April 10).

I have been very patient thus far and still am but the consistent radio silence on this issue is beginning to get frustrating…

@Edwin @Rainie @Alan @JKC20

2 Likes

M600 also doesn’t work as excepted on SM2

1 Like

Why I have the feeling we are talking to a wall with snapmaker team ?

I don’t see any improvement on this problem with the new firmware update ?

1 Like

Sorry for late response, while I was unable to reproduce the issue, I postponed it and I started learning firmware as well to reproduce issues you mentioned.

As I mentioned above, we didn’t modify the M900 command (I didn’t even use M900 before reading the topic).

After a few tries, I realized that why you failed to set K factor is that you were using the G-code generated on Marlin website. Commands with specific comment could be ignored by the firmware.

The line that sets K factor as below, these are two "K"s in the line which cause the G-code parser unable to parse the value (1.6) correctly.

M900 K1.6 ; set K-factor

If you change the comment to lower case, it will work as expected.

M900 K1.6 ; set k-factor

Edit: I did tested K from 0-2, but didn’t test smaller values like 0-0.2, wondering if the difference is visible…

1 Like

I will give this a try, thank you very much for finding the root cause of the issue!

1 Like