Hey all,

So my proximity sensor broke a while back while auto calibrating (like the plastic snapped and the sensor would just dangle). Anyone know where to get a new sensor, or has anyone come up with a better sensor that works with the snapmaker?

Hey all,

So my proximity sensor broke a while back while auto calibrating (like the plastic snapped and the sensor would just dangle). Anyone know where to get a new sensor, or has anyone come up with a better sensor that works with the snapmaker?

Can you read the part number on the sensor? Somewhat unrelated, but I’m interested in the Z3—part number on the side, but I can’t read it on mine and didn’t want to disassemble it.

But yea, any normally open contact from signal to ground will trigger the probe. There’s lots of options.

You can get it from Snapmaker support as a sparepart!

Incorrect, support says “I have to buy the whole unit”. Brent as far as the part number - I can’t figure out where I put it! I took off the sensor to continue printing (yay manual leveling…), put it in my bin of spare parts, and now it’s MIA. So if anyone else has their unit disassembled for whatever reason, I’d be appreciative of any help

for what its worth, the 3dp module itself goes for $115 which i felt to be pretty reasonable, but yeah a 5 dollar sensor sounds like a better buy

it wouldnt be too hard to rig up a microswitch to get you up and running until you get a better solution though

All of sudden I could no longer auto-level on my A350. So I did the “red-light test” with my spatula and no red light. While setting up my machine back in January, the red light showed up and leveling was never a real problem until now. I’m supposing I need to replace the proximity sensor but from the comments in this thread I’m not sure if that is possible. Can I get (and install myself) a new sensor from Snapmaker or do I have to purchase an entire new print head? Thanks for any help you can give me.

@Bluetarp apparently I guess you have to replace the head according to the previous comments. Guys, they really don’t carry replacements?

Honestly I’m about to do another Ir sensor conversion. I’m keeping one as a spare just in case but if you’re in the US I could just mail you the one I take out.

If your device is still under warranty (and even if it is not) do contact support. It really sounds like something they should replace under warranty if it just stopped working.

Thanks Artezio and brvdboss for your thoughts. I sent a request to Support but have yet to here back other than that they received my request. I’ll keep you posted

Thanks for your generous offer! Yes, I am in the US. I’m hoping to hear soon from Support, but if it’s not soon I’ll take you up on your offer.

One member did get them to send a new sensor. The IR board is so nice that I don’t need mine either. I am keeping it for now but yeah we could offer them up when Snapmaker doesnt wana send a replacement for some reason.

Thanks Moose; I’m kinda new at this game and not very tech savvy. What is an “IR board”?

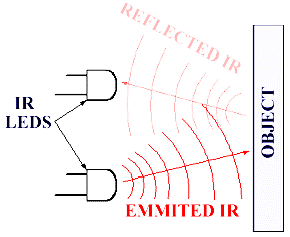

@Bluetarp An ir board is a board with led’s that emits infrared, it then reflects off the object back into the receiver led that tells it where that object is. This is just a basic explanation. There are different types of course.

This is a major improvement over the stock sensor, albeit requires a bit of tinkering.

However

It won’t work great on the black sheet. Its used in conjunction with a glass bed (which is also a major improvement, and one that is pretty easy to do)

That’s not true with differential IR. These differential IR sensors, as being used to replace the inductive sensor here in this forum, do return an analog distance if configured to do so. However the tool head is expecting binary functionality so that feature is not being used.

And while that is technically true for an inductive sensor, in the same sense a microswitch just detects the presence of an object, the way I’m reading your statement sounds like it’s implying that it is unsuitable for calibration. It has a sharp response that is suitable for calibration purposes, with repeatability in the +/-0.01 mm range from my testing

Analog output diffuse mode IR sensors are a thing, and I have some at work. PWM or 0-10v.

They wont fit here, though.

Banner Engineering, Keyence and SICK all make them for example. Along with ultrasonic, visible beam, radar, etc.

Ultimately, this is just a simple application and doesnt require any analog signal, just on or off is sufficient.

Yes, but you are too, we don’t need a distance measurement in this application, and the IR sensor specified here works pretty darn well actually, i was rather surprised.

I’m not familiar with those brands, so no.

However, I looked at their differential IR sensors and they are using the standard reference design nearly everyone selling those sensors uses. I think we’re at least in agreement with this specific point.

I don’t understand the repeated references to binary vs analog sensor outputs. A target height with binary output is what Marlin is expecting from the sensor. Analog outputs are useless for this firmware platform.

The textured surface causing measurement errors is a claim I don’t necessarily fully agree with. If you are suggesting the textured surface will return a non-consistent reading due to the small-scale variation in height of the surface, then perhaps, but the effect will be limited to the roughness of the material, which is a fraction of a mm (I don’t have the equipment to measure surface roughness but it’s apparent that it’s less than 1 layer height of filament when laying down the first layer so I would imagine this extends to the measurement error as well being smaller than 1 layer height of filament and therefore not a problem). If you are referring instead to the variable surface roughness scattering light in different ways that is the point of differential sensors, they measure relative to a variable baseline established at each measurement point, the sensor will not be affected by it.

Suffice it to say, if you are feeling brave or think you might in the future, look into that link i gave above. If you cant get snapmaker to get you a sensor, you can do this for about 50 bucks and be much better off, but it might be a bit early in your adventure to not go through the growing pains of dealing with the machine. the good part is we have a lot of people that want to help and its pretty well documented. the challenge is making the cable, but its not really bad.

OK, but this is about the guy who has a bad prox sensor thats all. Just trying to help the guy with some options…