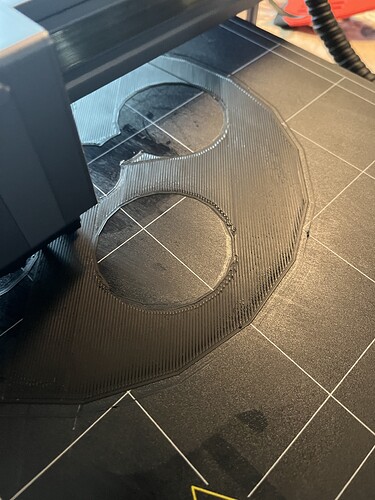

And here’s before for comparison:

Per my previous reply, this is how you calibrate on SM:

-S

And just as things started going well and it did print one project correctly……this started happening again on my 2nd print

If you have all the fundamentals right, like z offset, temperatures, leveled and clean buildplate etc…

I think probably some type of blockage in nozzle or above it…

These type of results are hardly caused by an untuned/uncalibrated printer IMO…

What is your retraction distance?

Gave the printer bed a good clean and gave it the “5x5” calibration.

First layer looks good so far……I’ll update as it progresses.

Sorry if I am not good at replying, but I do have a business to run

The lower part looks like underextrusion?

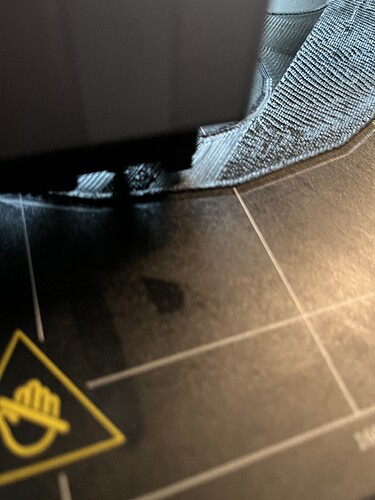

Something really doesn’t look right here those layer lines should be much more smooth…what size nozzle are you using? Can you post screenshots of your slicer settings?

It’s hard to tell without seeing in person, but from the look of the photo showing your second and third layers, it appears your first layer has severe over-extrusion, causing both your 1st and 2nd layers to drag through the filament, which will get worse with any subsequent layer, leading to a dirty nozzle and lots of balling up on the print.

Okay I think it’s some kind of “extrusion” Problem

Here I am trying to force feed the PLA through it

(Had to delete the first picture because you only allow one picture per post)

And already there you can see the difference in what it prints

I assume it’s way under extruded, so I assume I will have to recalibrate all this all over again

Based on the very limited information I have, my best guess would be that your retraction distance is too high, causing blockage above the nozzle…

Good luck!

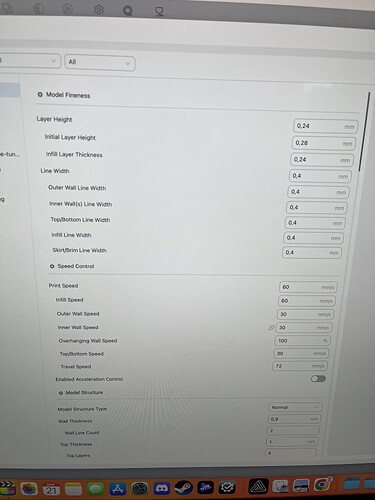

Before I start growing grey hair over this….

….is there anything here that looks completely out of place or looks off in anyway?

Does this sound familiar?..

Looks like exactly what is going on with yours, though yours is a more extreme example.

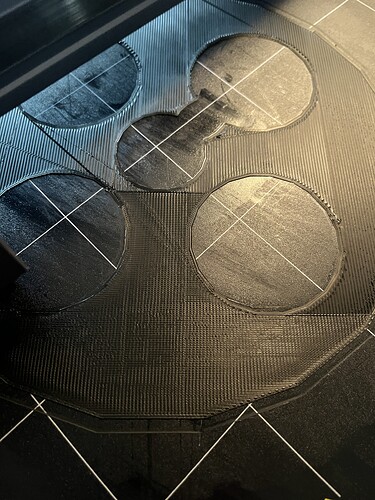

It’s DEFINITELY over-extrusion. I just tested it and got the same result.

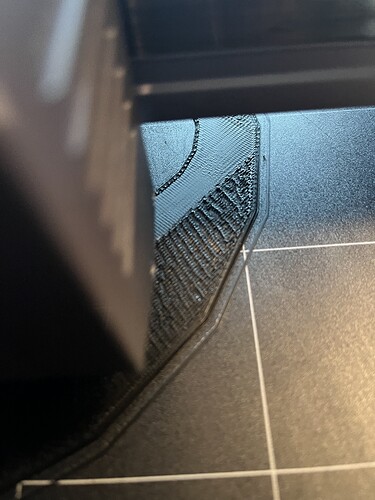

Top side…

Bottom side…

This issue can be deceiving. At first glance it can appear as under-extrusion because the bottom layer doesn’t stick to the bed all that well, and you can see the lower layers through the upper ones, but that is actually because the nozzle is dragging through the excess filament, ripping up the layers and clumping them up, then leaving those clumps along the print randomly when they quick sticking to the nozzle.

Ok, but what about this one from earlier in this thread?

From what I can tell, we’ve seen examples of:

-underextrusion

-overextrusion

-poor bed adhesion

My theory is that too high retraction distance is causing clogging/unreliable flow. Recalculating esteps will not help because the clogging above the nozzle is dependent on how frequent the retractions are…

My suggestion is to restore factory defaults and lower retraction distance to 1 mm, level the bed carefully with as many probing points as possible, try again (with way less % infill) and see what happends…

Okay……update time:

So I reset everything to factory settings….both the printer firmware and all the settings in Luban….then did the”5x5 bed calibration….then “Extruder calibration” and linear advance calibration….

Then set the “retraction minimum travel” to “1” and infill to 50%

Here’s just a 5x5x2.5cm test cube print in the making:

here it’s beginning it’s infill part:

This is on the factory “fast print” setting with the only changes:

- Retraction minimum travel = 1mm

- Infill = 50%

Not retraction minimum travel. “Retraction distance” you can find it in material settings…

Also “Extruder calibration” and linear advance calibration are supposed to take the printer from Ok results to great results. Not from terrible to ok…

The whole point of restoring to factory settings was to restore the esteps (extruder calibration to default values…

Over and under extrusion are not necessarily a printer issue; they can both be caused by the filament. Different filament types, different brands, and even different colors of the same type and brand can have very different viscosities. This is part of why the e-steps calibration is actually not dependent on the filament, and why variances in filament are supposed to be adjusted for by using the “flow” settings in the slicer software. But, if the filament is a poor quality with a lot of inconsistency, you can have both over and under extrusion in the same print, and there is really nothing that can be done about that except using something of higher quality. Bed adhesion issue can also be caused by over and/under extrusion, as well just form poor quality filament, or improper machine settings.

It’s kind of a crap shoot. At this point, I would probably try a different brand of filament and see how it goes.

Can you admins please fix this? ……this is not only stupid but since you only allow me to attach one picture per post, this just adds to the frustrations of the problem I am having.

See you in 3 hours gentlemen and ladies……or more like tomorrow morning as it’s getting late here

By the way; I really appreciate your help, thank you very much fellers