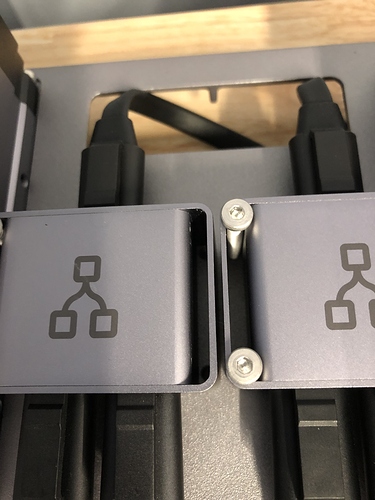

I finally received my A350 last week! My nephew and I put the unit together in about an hour. We ran our first print in about 3-4 hours without any problems to report. The instructions were easy to follow and I was amazed at the quality of all the parts. This thing is built to last. I only had two problems that shouldn’t impact print quality. We could not fit screws into two modules as shown in the pictures below. The sides were just too close for the screws to fit. The two modules fit tight so I don’t think I’ll request new ones. The unit is loud so I better invest in an enclosure as well. ![]() Other than that I can’t wait to start my journey into 3D printing with the new printer. Gonna try the laser and CNC modules this week to make sure they work to spec.

Other than that I can’t wait to start my journey into 3D printing with the new printer. Gonna try the laser and CNC modules this week to make sure they work to spec.

2 Likes

@Twix posted a similar experience .

I don’t know what kind of engagement the cables have. The v1 uses an RJ12/RJ45 cable head, so I don’t have to worry about the cables coming loose from vibration. Assuming the v2 has some similar locking mechanism, I’d consider what you did “secure enough”.