Hello everyone,

For about half a year I had good printing results with my Dual Extruder Snapmaker 2.0 AT350.

Recently I have suddenly had a lot of misprints. I have now thoroughly cleaned everything on the print head, including replacing the nozzle. I cleaned the print bed thoroughly with isopropanol. I have run through the integrated calibrations (X, Y, Z, leveling) both manually and automatically several times until I had the feeling that the printer is set up in the best possible way.

I store my filament in Polydryer boxes, they show about 25-30% moisture at the moment.

Now I have printed a benchy out of PLA for testing with the following result:

My settings were among others:

Infill: 15 %

Layer height: 0.2 mm

1st layer height: 0.3 mm

Speed: 90mm/s

With cleaning tower

Extrusion: 0.42 mm

1st layer extrusion: 0.5 mm

Temperature: 195 degrees

1st shift temperature: 200 degrees

Idle temperature: 154 degrees

Print bed temperature: 60 degrees

1st layer print bed temperature: 70 degrees

Fan: 100 %, with first layer off

Feed length: 0.8 mm

What recommendations do you have for improving my print image?

Thank you very much!

Regards,

I would like to talk first about the lost obvious issue: layer separating.

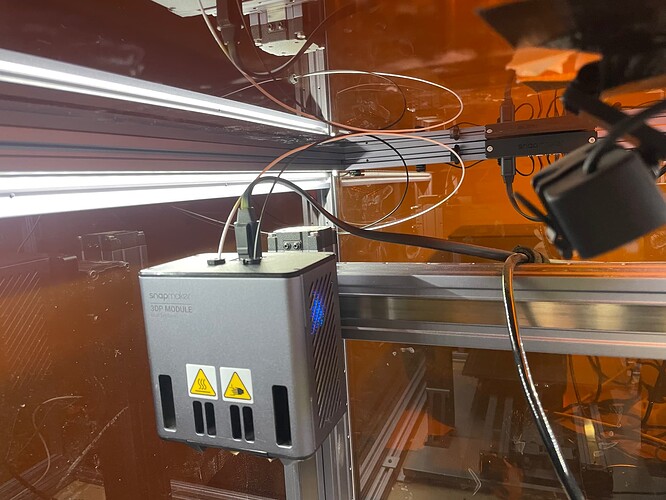

It seems your toolhead is partially raised by the counterforce of your filament spool.

Maybe your filament is tangled on the spool or your filament path is somehow mistaken?

Maybe observing the print would help to see if it’s printing I the air.

If it’s old filament try drying it. The moisture in the dry boxes could be less than 20%. Even changing to a new spool (even dried) could improve the result.

1 Like

Thank you for your quick response!

The filament is in the Polydryer box on the housing and is fed into the print head through the opening provided on the side of the housing.

I will definitely check the location again and try to optimize it, thank you!

I used freshly unpacked filament. I always regenerate the silica gel in the Polydryer boxes when they have changed color. If I know that I’m going to use the filament soon, I’ll put it on the Polydryer again. But I haven’t yet managed to get it below approx. 25% in any box.

With the new filament, I also had clogging for the first time and this happened twice in quick succession. Shortly after the extruder, the material had thickened and was therefore not transported any further.

I will disassemble and clean all the parts again tomorrow.

Regards,

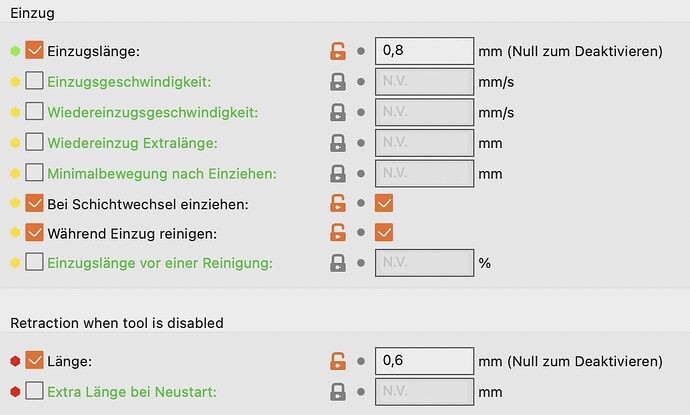

What’s your Filament change retraction setting? Clogging could also be an issue.

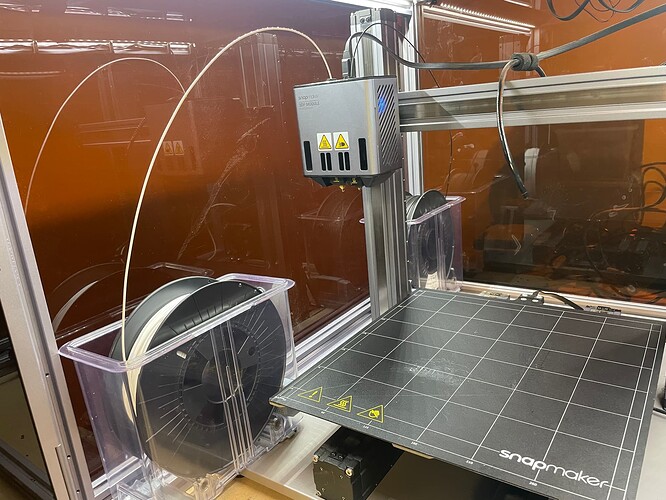

I rearranged the filament today.

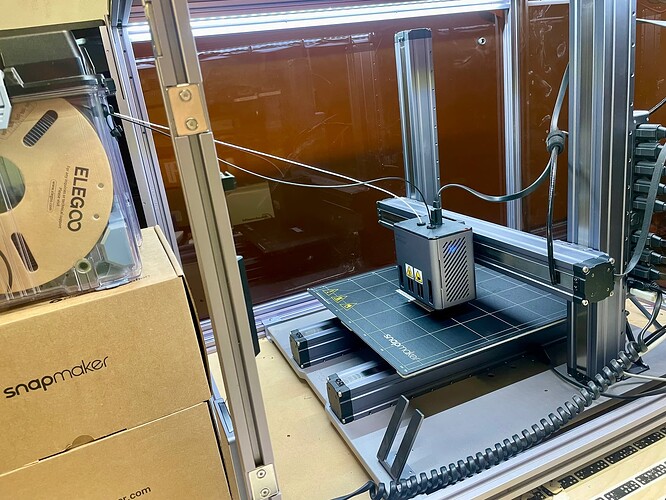

This is what it looked like before:

This is what it looks like now on a trial

The result of the benchy with the new arrangement:

Obviously at some point no more black came out. But nothing was clogged, I was able to extrude black manually without any problems after stopping.

My setting for the retraction when changing the filament:

I will look for the cause of my problem and would be grateful for any tips.

Thank you very much!

Regards,

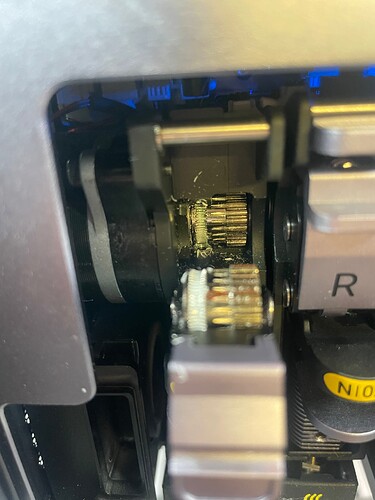

…while I was trying to improve things by recalibrating and leveling, the following kept happening:

After a short time, the print head always started to make cracking noises and no more filament was fed in. It sounded as if the gear drives had gone haywire.

It happened in both extruder 1 and extruder 2 and was not reproducible.

A lot of deposits have also settled there:

Do you have any idea why this is happening and what is the best way to clean the gear drives?

Thank you!

Cracking normally indicates bad feeding. Use the lid of the boxes, feed from below, use the ptfe tube directly from box to head so it wont tilt.

1 Like

My toolchange retraction for the disabling tool is set to 15mm.

It seems you are fighting with heat creep.

1 Like

Okay, I have at least managed to print a Benchy again:

The main reasons that made me able to print again were:

- Repositioning the polydryer boxes. However, this is only provisional for now, of course:

-

Reset all parameters with M502. Then, of course, recalibrated everything.

-

I changed the black filament. I had reopened a roll of 3Djake Eco-PLA and it seems to be difficult for beginners, as I have now read in various reviews. Now I have a roll of Elegoo PLA on it, which seems to work much better.

The stringing in the white filament is probably because I’ve had the Polydryer box open for a while now, right?

Where do you position your Polydryerboxes (or similar drying boxes) during printing for ideal filament guidance?

Do you have any other tips to optimize the Benchy?

Thanks for your help so far!

Regards,

1 Like

Me again…

I’ve now run another longer print, which has unfortunately become quite rough and bland at the top:

On the left is the same part that I printed before the “printer breakdown” and where I was very satisfied with the result. The Gcode is the same, so nothing has changed in this settings. The filament is different (previously Snapmaker PLA, now Elegoo PLA).

I am also happy with the underside of the print:

So something seems to have gone wrong again towards the end. I now have the filament on the Polydryer again and will then print a temptower. Do you have any other tips for me?

Thank you!

Regards,

Try printing with a purge tower, it should take care of a fresh filled nozzle.

I think this could help with the bad black surface around.

The white parts are too hot printed, I guess.

Temp tower is a good idea

1 Like

Thank you for your patience with my progress!

I think the Temptower is quite well done.

However, I don’t recognize much, except that the stringing is lowest at 195 / 200 degrees.

What can you tell from the pictures?

Thank you!

Is the temp tower correctly printed, with different temperatures?

Maybe it’s was not clear for you thats necessary to adapt the gcode or to do it in the slicer..

I mostly print pla with 190°C and I think it’s your setting as well.

1 Like

Yes, i edited the gcode and checked while printing.

It increased the temperature by 5 Degree always at the correct Layer…