Hi all

I am looking for tips on how to keep the size of a drawing / 3dObject when working with different tools and exporting/importing the item.

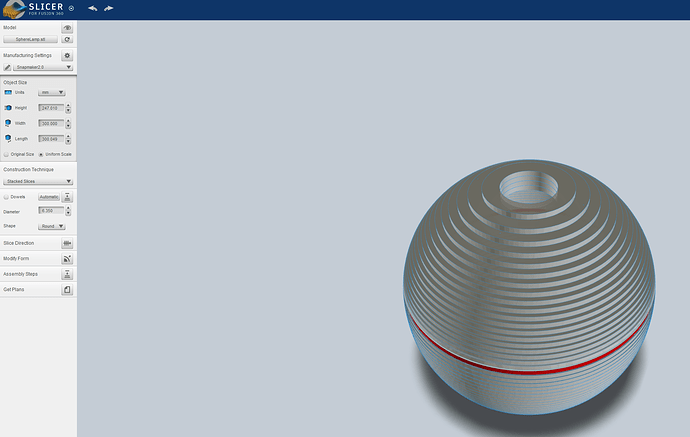

Currently i am trying to build a lamp like the ones shown here on this picture out of cardboard using the laser cutter:

The tools i am using and their purpose:

-

Shapr3D to create a hollow sphere with proper mesurements (300mm diameter)

-

Fusion360 Slicer to create the slices

-

Snapmaker Luban to bring it to the laser

My problem is that after exporting the STL file from Shapr3D and importing it into Fusion360 Slicer the sizing is totally off. This is not a big problem as the Slicer app allows me to set the workpiece size. So i change it back to 300mm and it’s fine:

Now the next problem is when exporting the DXF (units: mm) files for each slice, actually there are two problems:

-

Layer numbers and alignment marks are “printed” in red on each layer and i don’t see an option to turn this off in the Fusion360 Slicer. As far as i understood some laser cutters or other laser cutter software is able to recognize this as engraving and the blue lines as cutting. Snapmaker Luban does’nt seem to be able to do this. So i somehow need to remove these marks but sadly in Luban the numbers and marks are not selectable but only the whole layer. This leaves me with the only option to again open each slice in another software (i tried fusion360 and inkscape) and remove these marks. Here also the sizing is not correct anymore…

-

When opening a layer in Luban the sizing is off. I mean it’s not a huge deal as i can set the size manually in Luban but i need to do it for every workpiece and it is prone to errors and there is some uncertainty that everything aligns in the end.

I think it would be so much easier if I was able to remove the marks in the Fusion360 slicer which would allow me to directly import it into Luban and set the size for each layer manually. Even better would be that the sizing stays the way i set it in each tool.

So long story short: Does anyone have expirience with such processes and can give me tips or hints on how to approach it?

At this point, thanks for reading that long text and thanks for your help in advance ![]()