Regarding the strength of the printed parts. It depends on what oil is being used and how much. In general while printing PLA, machine oils are usually bad for layer adhesion while vegetable oils can have the opposite effect.

By adding small amounts of fatty acids, plastics typically becomes more waxy and slippery. while that does not strengthen plastics, my speculation is that since the nozzles are bad at kneading plastics, the addition of fatty acids makes the melt slightly less viscous(easier to knead) and thus create a more uniform extrusion melt

May higher Temps will Fried your Printer. The Oils in Pan on 200 or more can Burn

No, the problem is the “plug” you get when softened (but not yet liquid) filament is compressed axially from the extrusion force. This results in a “plastic cork” just above the melt zone of the extruder. Frequent retracts increase the severity of the issue.

If you burn in a frying pan, you deliberately heat it up several times well above the smoke point, each time with a thin (!) layer of oil in it - I use about 250°C in the oven for my pans. The oil will slowly polymerise then - first it gets sticky, then it hardens even more and forms a hard layer that works almost as good as a PTFE coating if handled correctly - with the added advantage of being renewable by repeating the process. This is how virtually all frying pans worked prior the invention of Teflon - you simply cannot fry in an iron pan without this layer ![]()

Such a layer survives the heat the pan gets while cooking, which can be up to about 280…300°C if I am not mistaken. But I do not know what it does at higher temperatures, - sooner or later it will degrade. And you need to feed it with new oil, just as you would do with your pan.

I use iron pans this way too. Never cleaned with soap.

But on the extruder im not sure what will happens if you do that on long terms. Ive seen some people do that and I know from one that has some issue on the head, I mean it was an thermal runaway and with that oily stuff it’s get lighten up even more

I don’t will do that to my printers.

If I want shiny or glossy stuff I use silk filament.

(May im a Old School Dude) ![]()

![]()

But if it works for someone, it’s ok. It’s not my fryer, aah Printer ![]()

I won’t do that either - my printer is my printer and is not supposed to smell like a french fry shop ![]()

But others do use it successfully.

I had yesterday the abnormality that after the last firmware update the clogging an skipping is more worse… I used same G-Code an Filament…

I’ hope that someone in the community has a permanent countermeasure for solving this issue because the printer itself is a very good device.

Hello everyone,

I would like to give you another small update.

I’ve been printing without any problems since the optimization.

More testing is pending, but it looks very good that it will stay that way.

Not long now, if Mechanikus and MrBean can confirm my findings, we will be able to publish a solution in a timely manner.

German:

Hallo zusammen,

ich möchte euch noch einmal ein kleines Update mitteilen.

Ich Drucke, seit der Optimierung ohne jegliche Probleme.

Es stehen noch weitere Tests aus, aber es sieht sehr gut aus, dass es so bleibt.

Nicht mehr lange, wenn Mechanikus und MrBean meine Ergebnisse bestätigen können, werden wir zeitnah eine Lösung veröffentlichen können.

Good news. Hope that works and we can do that on our printers soon. Got much clogging here.

I use one of my other printers at the time, they much slower but don’t clogg always

No more clogging, just a simple fix ![]()

take out the Hotend from Extruder Heads, replace the cooling fan from heatsink with a better one with more Airflow. you can also alow them more airflow from outside and print a cover with more vent holes and on the other side where the fan blows the air out the hotend you can remove brakets from the cover, so the air can be better go out and its reduce fent noise

Put thermal Grizzly Heatsink Paste on the Heatbrak.

No more clogging here.

Printed PLA, PLA silk, PETG, HIPS, PVA, TPU and ASA.

Some other tests are running.

Next time may be put in the Bondtech gears and the other heatsink. ![]()

So i only need new rails, the rest seems ok now

Can to provide the fans you used?

I use this fan for my testing.

But I order some Sunon and some winsin fans to find out witch one has more airflow and may runs a bit quieter.

Under the screws I use some Rubber Bumper for the space.

Do you have links to them? Pretty hard to find better fans…This brand seems not to be available anymore?

I can use the Sunon fans too. Got them from amazon

Ok, but they are not stronger than the original.

I testet both. Both have more airflow. You can make the fan test from thingiverse

Here are the guides on the clogging/filament not extruding troubleshooting flowchart and general solutions. Please note that general troubleshooting content is aimed at providing an instant guide as a self-support resource. It won’t be helpful 100%. However, you can contact the support team to do deeper troubleshooting. The support service is also important. https://snapmaker.formcrafts.com/support-ticket

- Troubleshooting flow for clogging/filament not extruding (J1)

- Inappropriate print settings cause a clog

- False trigger of the “Failed to Load Filament” error (J1)

- Extruder drive gears are not aligned/Extruder driving gear set screw is loose (J1)

- The extruder is clogged (J1)

- The hot end or nozzle is clogged (J1)

may I ask if there is already a solution that can be published? Thanks

unfortunately I also have a J1 with this problem…

Hi smike,

here you can find solutions:

I will rebuild my hot end this week and post the parts in the topic above end of this week if it works.

It seems that this is one of the major (designed by committee) flaws in the J1, along with an ever increasing list of others…

Surely they should be able to give us this information from there design data…? i would personally preferer a variable “pressure” adjustment on the load to the mechanism to compensate. ( the spring should just act as a dampener)

I find that the harder the material being printed is the more pronounced this problem becomes (i.e. GITD PLA is the worsted and SBS, TPU is the least affected.

I have even switched to Diamondbak MK8 polycrystalline diamond tips in the hope that the much higher thermal conductivity and low coefficient of friction would alleviate this problem by reducing the amount of back pressure and force placed on the feeding arrangement.

Even 0.8mm hot ends with many times more open area than the 0.4 mm nozzle has little effect on skips, i have however not experienced any clogs.

It seems like the design committee had no lack of very good ideas but somewhere between concept and commercial product, there was / is a massive disconnect.

a real pity would have loved to be able to report that is is a brilliant piece of equipment.

I am busy compiling a detailed list (and pictures / videos) of problems experienced so far. it is quite staggering to think we paid over 1000 SD and waited months for a piece of hyped up “junk” (sic) that has not produced a single clean print, has damaged itself, shows a total lack of qa/qc in manufacturing, assembly, accessories, software or firmware.

But hey this is just my consumer experience with them, what do i really know or matter to Snapmaker.

On the subject…

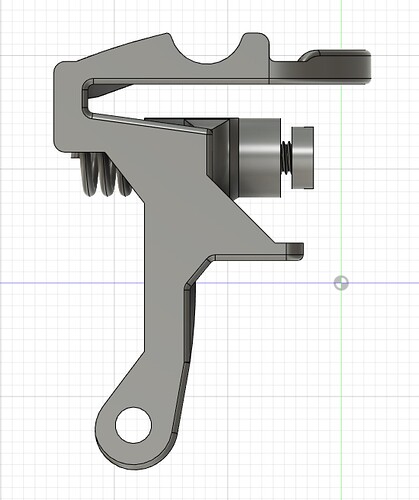

I had initially also thought that you have to find a solution for this and had designed a solution for this.

An adjustable filament guide.

It fits and works, however it was no longer necessary since we found a solution with a new heating bridge that works.

I have tested with the heating bridge solution all filaments that I could find, meanwhile spent over 500, - € just for filaments to be able to test everything possible.

Only one filament caused serious problems, it was the PETG from https://www.filament-pm.com/.

I could not persuade it to print, but I already had problems with it on my old printers, only a Bowden extruder could process the filament.

And now seriously, stop complaining!

The printer has basically an excellent conception, things of any kind there are always that make problems, we have worked out an excellent solution for this, which is also easy to implement.

So please …

I have yet to have a printer that did everything perfectly from the start.

But if you are interested in an adjustable filament guide, I could possibly rework that.