After few bad prints… I restore it to factory settings and now it can’t even calibrate. The head goes so low that it scratches the table and I have to turn it off in an emergency…Can’t manually calibrate either…the calibration menu page is blank until after a successful auto calibration…auto calibration is failing…z axis proximity sensor must not work as print nozzle strikes print bed hard…never calibrates.

Hi, very sorry to see this. Have you tried to contact support? You can submit a support ticket here:

https://snapmaker.formcrafts.com/support-ticket

I have been trying support troubleshooting for a month now… nothing has reset or solved the calibration issue

finally we solve the problem , i write u what we do after few test

VERY MUCH looking forward to hearing about a solution

what have we done:

when the printer is turned off, you need to move the z axis to the very top and only then turn the printer on so that it knows that it is in the autohome position (when the z axis is at the top then it touches the limit switch)

then you turn on the printer and start 3 step calibration, but remember! to put a sheet of paper all over the table! this will protect against setting the print head too low and tearing the table (this is an option only for a moment to go through the 3 steps of automatic calibration)

when the printer does all the points and you can set the table manually - you choose manual settings in 25 and manually set 25 points yourself. After this procedure, our printer started to print normally. unfortunately, due to the problem of hitting the table and abrasion - the nozzles are suitable for replacement because they are worn

Ok… will attempt this.

So this did not fully solve the issue but it did produce different results and advanced 1 additional auto calibration step than before

-

Initial auto z calibration did not strike the glass bed hard

-

X and Y calibration did lightly scrape the glass bed

-

Both auto x and Y calibration did save ( y would not previously save)

-

Multiple error screens ( pics attached)

-

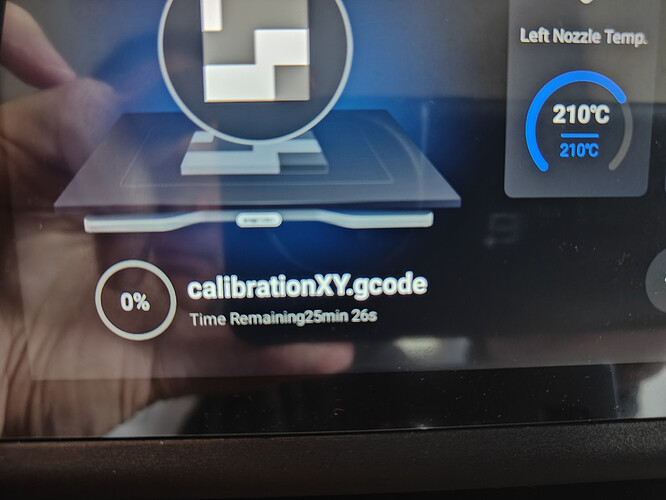

Stuck at print check model (5/6) xy offset calibration. Nothin moving. Percentage complete never rose above 0%. Oddly the time remaining clock counted up…not down

Repeated a second time.

Made it past auto calibration

Performed a manual z axis calibration

Attempting a print now

Print didn’t work

First 2 layers mashed together

I had to add + 0.4 mm of first layer z hight for the left extruder as soon as I start a print after calibration.

And 0.3 mm z hight for the right extruder.

The first time ever I printed on the machine I didn’t have to do that. But afterwards I had to add those z hight adjustments (from the console) after I start the first print after z hight calibration.

Also print and install the extruder wedges if you haven’t. They’ll make your life a bit easier and might solve your printer issues.

Ok. Did that…and it worked except…

The last attempt at printing the Right extruder nozzle did not retract and mashed into everything the left nozzle was printing…but we are almost to a functional printer…so that is great

Sorry you might be frustrated. I have forwarded your issue to our team.

Would you please share the below info with the support so that we could help you fix this issue asap?

1. Please take a video of the machine returning to the work origin using the control interface’s “Home” function. The video should capture the entire machine.

2. Please take a video of the Z offset calibration process. The video should capture the entire machine.

3. Please take a video of the Heated Bed Leveling. A 5x5 point Calibration video is sufficient.

If you are unable to complete the calibration process, please unplug the printer head connection cable, enter the settings menu and restore factory settings, then reconnect the printer head and enter the setup guide. This will allow you to capture these three processes on video.

And at the same time, please send the system logs to the support. To export the system logs, tap Setting → About machine, scroll down and find the System Logs column, tap Export, and then tap the export method you want. Then please find the log files (named FW & SC) in the USB drive and send the files to the support.

Once you have submit the above info to the support, would you please provide the ticket ID to me?

Thank you so much!

Question about moving the Z axis back to top, did you further move print head to far left, (which I think is the home position) or just mover it the very top as mentioned, as I’m the boat as ‘Adshijw’ pulling my hair out.

Was there any solution to this? I am having a very similar issue. I am wondering if it might be something with the dual extruder and I am going to try to follow: https://wiki.snapmaker.com/en/snapmaker_artisan/troubleshooting/extruder_r_failed_to_home

Moving the head all the way to the top was something I found very bizarre. I did it because I could tell the printer thought it was at the very top but was really about 10 mm above the table (craziness). I am surprised that it didn’t move all the way to the top… It typically does this.

So for further context, I had been using milling and laser functions just fine and I wanted to 3D print a part (which I had done before AKA this isn’t my first time). So I swap the head and table. I proceed to do the auto leveling feature with the max amount of points (9x9) and then I continue to do the Z calibration and XY calibration. I had finished the XY calibration and the printer was going to do its check print. I left it for a while so it could print but came back to find it had not printed anything. I got the error message saying that extruder had been pulled or whatever, seemed normal and I could not continue the XY check print. So I stopped it and went to redo the XY calibration. Next thing I knew the printer slammed into the table. This was not after a power off. Now I am in the same boat as ‘Adshijw’

So it looks like the factory reset did the trick for me.

When the extruder is pulled up, you have to check your filament path.

Be sure your filament spins free, is not tangled and it’s as less counterforce to the extruder as possible.

The spring in the dual extruder is not very strong so it has to be well assembled.

So here I am months later ready to do a 3D print job after doing several other operations. Same issue. Am I doomed to factory reset the Snapmaker EVERY time I switch back to 3D printing?

This is not during 3D printing this is during calibration. Reverting Firmware indicates it is not a Hardware issue.

How do you factory reset? M502?

I have been going to the settings and doing the factory reset. Though this time I have the same issue after factory reseting…