Just pulled the trigger… Mid-July delivery.

@Skreelink thank you verry much for the clarification’s.

I’ve seen that, but my trust in such vague replies is limited… Well, I’ll try it out if I have the device.

Regarding the additional needed Plates Snapmaker Staff seems to be unsure aswell.

In the Main articles comments someone raised that question and got told: yes you need an additional plate.

Then Staff posted a wiki link:

There is no such plate found.

Instead under point 7 note 3 its stated:

3) lf you chose the Artisan model, your order will come with an adjustable version of the Quick Swap Toolhead Plate to make it compatible.

So ill guess you dont need an aditional plate nor it seems you could buy one.

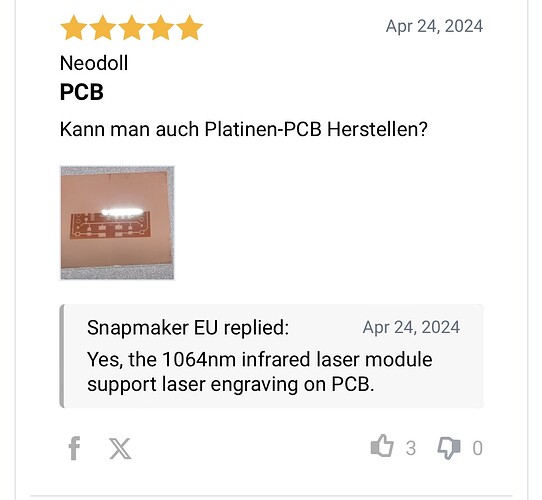

Regarding PCB:

For me thats one of the main selling points. I hope it will do well but still im unsure cause Snapmaker told a lot of stuff that was not exactly what we got and didnt correct that till this day.

Greetings

Indeed it’s good to stay skeptical, maybe they’re just saying you can use it to laser a logo into an existing PCB ![]() . Guess I’ll find out and hope I won’t get burned (both figuratively and literally).

. Guess I’ll find out and hope I won’t get burned (both figuratively and literally).

Laser is delivered for mid-August!

Hello, I have bought all Snapmaker modules so far, some of them I even have twice ![]()

![]()

See below the most definite “official” answer I’ve yet seen - I guess I can look forward to a very useful tool addition! That expands my workshop capabilities considerably. I’ve done isolation routing with CNC, but getting the PCB board absolutely parallel to the toolhead plane is a PITA, and I’ve kindof given up on that. The laser should be much more tolerant to minor tilts…

Thank you!

Sounds very promising.

Ordered mine as one of the first cause i see some more benefit in the 1064 laser than in the 40W which is only speed.

Proper laserengraving on Prints or stuff like that seems tempting too and to be fair:

For a Snapmaker Product the price is fairly resonable.

Lets have some Fun with it ![]()

Same here. The 10W currently gets me everywhere I want as far as blue laser goes.

Huh, yeah… not really. I again find it more on the expensive side - I had a coupon available, otherwise I’d have had more hesitations… Actually, I do not understand Snapmaker’s pricing. The bracing kit: about 100 € → expensive IMHO; The bracing kit PLUS 200W spindle about 250 € → very reasonable…

Whatever…

Nice! I was wondering if the IR would do glazed tile. So, you didn’t pretreat the surface with e.g. paint or anything?

No surface treatment at all.

I do have the QSK on my A350. And yes, the laser does have the same back mount as the 40W.

I do not have any PCB on hand, but I have been able to cut into copper plate and brass plate with the IR laser.

My only real question is: Why 2w? Why not start with 10, 20 or 40? I don’t really want to pay money for the 2w (again) and have it step up to a more powerful laser. I’m currently the proud owner of a 2w and 10w laser trying to decide if I should get another 2w or the 40w. I’m a general purpose user (which is why I got the SM instead of a better, single purpose, machine in the first place, so I have consider as many use cases as possible.

I’m not an expert, so what I say is a bit guesswork, but IR lasers seem to be a different kind of beast, and 10, 20, 40W IR laser diodes or other devices that would fit into the toolhead just do not exist (yet), or not for consumer-friendly prices. If you look around for 40W IR laser cutters, they all use classic glass-tube resonators/optical pumps, which require water cooling etc.The tube alone is 50-70 cm long - try to fit this into the confines of a Snapmaker toolhead ![]()

Edit: Here’s a pictue of the laser tube of the “famous” K40 laser cutter: https://raspi.tv/wp-content/uploads/2018/02/Rear-of-K40-Chinese-Laser-Engraver_700.jpg

I assume you meant 1.6W, there was no previous 2W laser on the Snapmaker platform.

Also, as @Hauke pointed out, it’s a completely different beast. Blue diodes and IR Diodes are on opposite ends of the spectrum. Despite only being 2W, it creates a massive amount of waste heat, making the unit itself huge. For comparison, despite only being 2W, it’s the size of the 20W laser to get enough cooling through it.

Also, if you happen to look up other 1064nm IR lasers from other manufacturers, 2W is the highest you’ll generally get. Any higher and you’re looking at CO2 laser tubes and systems like the above mentioned K40.

Also back onto the subject of them being different; keep in mind that power levels are not everything. Despite being a whopping 40W, the 2W IR will engrave metals faster (the limited metals a blue diode can engrave anyway), and other metals that the 40W can’t even touch (such as bare aluminum). It’s more about the difference in frequency and what materials absorb it.

Currently, all the lasers from their original 200mW to their 40W are 455nm blue diode. Which is readily absorbed by organics like leather and wood. The IR laser is 1064nm, the much longer wavelength is better at hard materials, such as metals and plastics. Also the overlap on materials that “work” also have differences. Such as black plastic.

The blue diodes can melt/cut/engrave black acrylic, PLA, PETG, etc. However, for a bright, contrasting engrave? IR. The below was done at 6000mm/min, 50% power with the IR.

Also things the blue diode absolutely cannot do;

Hopefully that helps clear up the confusion of “why not more power” and a bit of why they’re offering it. ![]()

Aluminum foil cut! ![]()