Verification record of Y-axis and Z-axis bump (impact sound)

I currently have 6 linear modules, and I am at a loss to solve the bumping sound of Y and Z axis with any combination.

The A250 assembled with the combination that seems to be optimal generates bumping sound like this.

Changing the combination results in a much worse bumping sound.

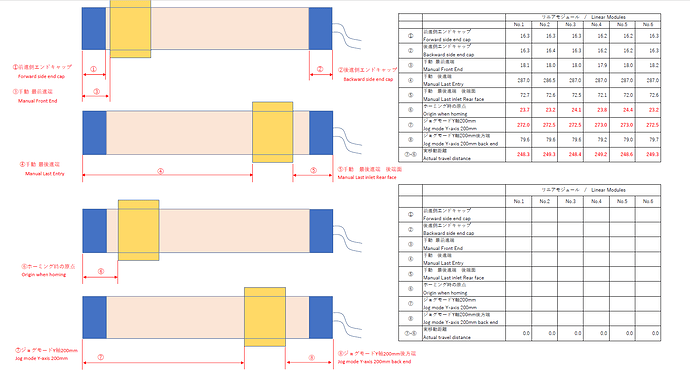

Attached is the result of measuring all the linear modules.

From this, we can see that the best way to eliminate the bumping sound is to prepare two of the same dimensions.

Even so, if there is yawing in the rotational direction due to separate fixation or other reasons, or if there is an oblique inclination to the axis, bumps will occur.

If you are having trouble with bumping noise (bouncing or misalignment due to the impact of the bet), you need to measure the dimensions and select two linear modules with minimal difference each.

In my case, the bumping sound has not been eliminated in all combinations…