Hi all!

I’m trying to figure out how to reliably and efficiently (without a bunch of manual g-code change) work within full limits of the machine.

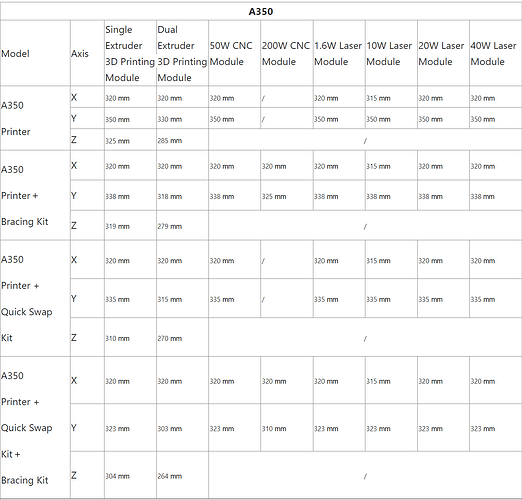

For starters, I’m aware that official spec is a bit below these numbers.

But, open your Luban console, home your machine and check it’s coordinates

For the purpose of simplifying things, I will concentrate on X axis here.

My X is at -19. My Max X is at 338 - put these two numbers together - I get 358.

So If I run the following code (via Luban console)

G0 X-19 F1500 ;Go to start of operation

M3 P100 ;Turn on the CNC spindle at full speed

G0 X339 F100 ;Move tool head to the limit of the actual work area (X358=19+338) with feed rate 100mm/min.

I’m able to use the full area to cut the material.

However, if I’m uploading a project using coordinates outside of the 320mm in X - it gets mushed. Similar to what you experience with Dual Extruder 3D printing, when right nozzle is outside work area or with laser. To illustrate, this is what happens to the project after it gets processed by firmware.

You will get a failed print/laser job or CNC job.

It seems like the in order to combat this, something within firmware has to be adjusted. Researching the Marling documentation - Configuring Marlin | Marlin Firmware I found that the following might be something needed to be changed

#define X_BED_SIZE 200

#define Y_BED_SIZE 200

#define X_MIN_POS 0

#define Y_MIN_POS 0

#define Z_MIN_POS 0

#define X_MAX_POS X_BED_SIZE

#define Y_MAX_POS Y_BED_SIZE

#define Z_MAX_POS 170

But searching the Github Repo doesn’t seem like these are defined…

Granted, I’m no good at #C.

thus the journey continues. I invite you to join…