I’ve had some decent PETG results, but I would definitely caution against printing directly on the bed. I did it once and it almost ruined my print bed. There are still remnants of it that I can’t get off, and I might buy a new bed because of it which is about $35. I got some Overture filament, and there free print bed stickers seem to work perfectly with PETG - it pops right off warm or cold, and seems to stick well.

As I said earlier in this thread, glue stick works great with PETG.

Not a fan of hair spray just because anything aerosol is going to go places I don’t want it to. (Just a personal preference).

-S

Since the print bed can be removed easily, you can spray it somewhere with good ventilation. I sometimes use gluestick, but it does not result in nice surfaces sometimes.

i tried the gluestick thing and its fine but i really think magigoo is the best of both works, because it helps release the part and its super easy to clean up and touch up or reapply

Can someone please share his or her PETG settings in a .json file. At the moment I’m despairing to get a the settings right.

Best regards

I had trouble with PETG at first, but after reading a different thread on the subject, I started using card stock instead of the included card for my Z calibration. The prints looked great after that aside from some stringing (but it’s PETG, so that’s kind of expected). It’s also really important to have a level bed - make sure you heat the bed before leveling (70C). I use the Simplify3D slicer which allows you to keep the heated bed on while using the leveling feature on the LCD module. The biggest issue I’ve had is the PETG bonding to the build plate - I ruined one build plate trying to get it off. Using glue stick first prevents that from happening.

Thanks for the reply ;). Still I would be very thankful, if someone could give me the settings for PETG. I’ve no Idea how to get started (which speeds and so on). But the hint with the glue stick is very helpful I will keep that in mind.

Search the forum for PETG and you will get a lot of results and also settings.

Have a look at this comparison of 3d printing materials:

I normally use this settings:

Heated Bed : 80°C

Nozzel Temp: 235°C-250°C

First Layer Speed: 8-15mm/s

First Layer Height: 0,2mm

Printing Speed: 30-50mm/s

Layer Height: 0,2mm

Just wanted to say thank you for this guide.

I’ve been struggling with Verbatim PETG over the weekend.

Print temp - 235⁰C +/-10⁰C

Bed temp - 90⁰C

Also the Snapmaker PET-G using the default luban settings.

Using the provided info I’ve gone from a snotty stringy mess to a passable print.

I also raised the Z axis by 0.05mm compared to the PLA setting/calibration.

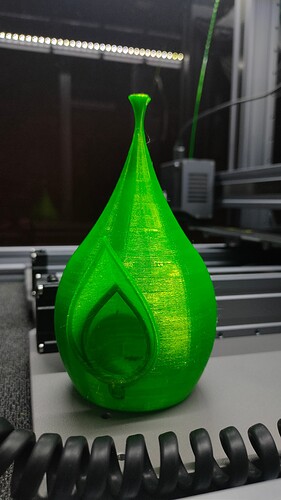

Sorry to bang on just how happy I am that the above setting suggestions worked (with Verbatim PETG Translucent Green).

A little fuzzy on the inside, but it cleaned up well.

Now to scale it up and learn a little patience.

Currently trying to get to grips with Prusament Jet Black PETG and I’m back to square one.

I know others will probably disagree, but I just got some of the snapmaker PETG (yay freebies from signing up for their marketing texts), and it printed just fine using super slicer and my matterhackers PETG profile.

The problem with SM filament was mostly the black PLA that they originally sent.

And it was mostly a problem with inconsistency. Mine was fine but a lot of other’s people was crap.

Free is good though. (unless you spend so much time tweaking it that it cancels it out)

Lots of better and cheaper choices than SM filament out there.

-S

I’ll give it a go.

I used the Prusa material profile for their PET-G in Cura and adhesion was an issue.

After a few attempts with Luban I managed to dial it in.

Interesting how SM, Verbatim and Prusa PET-G all require their own little tweaks.

I’m treating as a learning experience.

I’ve only had my machine (Snapmaker 2.0 350T) for a week, it’s an amazing machine! I have the Luben 4.1.3 and the latest firmware. I’ve been creating amazing things using PLA, and also using the laser head with both cutting and engraving.

I’ve been having awful trouble using PETG, but I think after a couple of days of trawling the forum and continual cancelling of prints that glob up, I have discovered my issue at least. It seems to be that the machine is not printing with the correct nozzle temp or heated bed temp, even though I’ve definitely set it correctly in the profiles.

I started looking in the gcode files, and all my files, regardless of material selected, all have the same heated bed temp of 60c and nozzle temp of 205c.

I edited these lines in the header_type section:

;nozzle_temperature(°C): 245

;build_plate_temperature(°C): 75

I then searched for M104 and M140 commands which set the temp for the nozzle and the bed and changed them to the desired temperature:

M104 S245

M140 S75

After changing these settings, saving the file, importing it in the Luban workspace, and sending it to the machine, it now prints first time.

So there seems to be a bug, at least in my setup, whereby it ignores any settings that I have in the Luban profiles, and just puts the same defaults of 205c nozzle temp and 60c bed temp into all gcode files.

A quick summary of workflow:

- Import .stl file into Luban.

- Select material settings profile.

- Select Printing settings profile.

- Set general parameters

- Generate G-code

- Export G-code to file

- Save to an easy to access location like Desktop.

- Open file using a text editor. On Mac, BBEdit is good, on Windows, Notepad++

- Use the “find-all” feature in the search function to locate M140 and M104.

Change the incorrect values to your desired settings. (Don’t have the S0 value as this is when it turns the bed and nozzle temp off after printing is complete). - Save the file.

- Back in Luben, go to Workspace.

- Click on the import button in the “G-code files” panel which is the box with an arrow pointing into it. Find your file that you just saved and load it.

- Send to device.

- On the snapmaker touchscreen, go to files and load the file you just sent.

- It should now have the correct temps in it.

- Start your job

I hope this helps someone, and I hope if it is a bug in the software it can be fixed.

Thanks everyone for your help with this through the forums.