Hi,

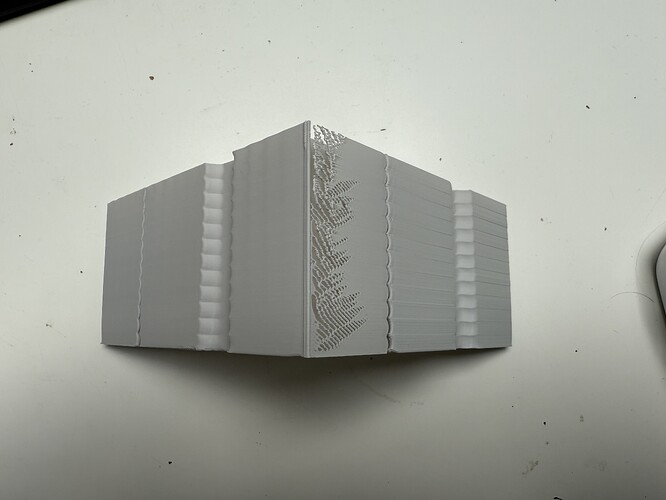

I am owner of a used snapmaker a350. When base plate change direction it shakes. I have printed vase but in top layers you can see sinusoidal pattern in 2 points. I tried beta firmware with vibration compensation but on a test print one side look ok, the other one does not. Are base plate linear modules broken and need replacement? Thank you for answers

This is a kind of underextrusion.

This could be optimized with Linear advance or slower printing speed or higher print temps (if it’s speed is really fast).

The beta of Snapmaker Orca is well tuned for the Artisan. I went through the calibration prints for flow rate and pressure advance and they were spot-on. I would expect the dual extrusion module on any of the Ax50 models to be similarly tuned.