I want to test a slicer other than Luban or Cura for my A250 printer. The decision fell on OrcaSlicer. However, I’m not entirely convinced about the default settings for Snapmaker A250 printers. After generating a sample print program in OrcaSlicer, at the beginning of the code there are NEW parameters for the printer, which are significantly different from those in the printer memory.

Code fragment from the program::

EEPROM fragment:

I fiddled around with the slicer settings a bit. I managed to enter new data so that the “new data” were identical to those from the printer.

I only have a problem with finding and setting the M205 command. It is stored differently in OracSlicer than in EEPROM.

Do you have any suggestions on where to change it or whether to touch it at all? I don’t have much knowledge in these matters myself.

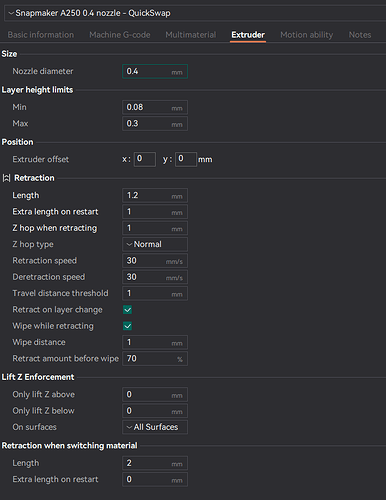

For those interested, I’m posting screenshots of my settings in OrcaSlicer (not tested yet). Maybe you can advise something else here too.

The size of the working pore is set to the QuickSwap Kit and the head with a single exstruder.

X=230 Y=235 Z=235

Thank you in advance for any advice ![]()