I saw a lot of posts on this issue. Too many to read, What I have discovered with my my J! is the fan is cooling the nozzle so much it is creating a plug at the tip. I do not have the problem with ASA because no fan is used, Turned off fan with PLA and the plug-up has completely stopped. Many hour prints, no more plugs!!

My plan is to put tape or some sort of blockage on the fan outlet in line with the nozzle. Or some sort of air splitter so cold air does not blow directly on nozzle.

Big issue simple cure… Try it.

Im trying this tonight. It’ll blow my mind if it does anything for mine ![]()

I have done some more investigation. The fan is a contributor. But I found I still had extruder stall on some prints. From day one I knew the J1 was overfeeding by 10%. I was running a 90% flow on all prints. Now I have discovered the overfeed is actually 20%! (At least on my machine)

I blocked the center of the fan with about 8mm piece of tape (both extruders) I am going to run fan at 50% for most PLA prints. I have reduced flow on PLA (Overture) to 80%. I am getting excellent prints and NO EXTRUDER STALLS what-so-ever.

I think Snapmaker needs to confirm for themselves and update the steps per millimeter for the feeds in the J1.

There is a lot of calculations going on the in the firmware. I took the side off one extruder to examine the interior. The orange button in the top is a spring loaded filament flow sensor. So that data is going somewhere. I was also having concerns that the extruder feed groves that grip the filament were not exactly in alignment. By eye, they don’t seem to be in line. But there is probably enough “wiggle” in the clip door as it slides on a hinge pin.

The two problem areas I see are the huge amount of air blown against that tall Nozzle (There is a reason for the short fat ones) and certainly the high material flow rate.

High speeds need high flow rates but not all my prints are high speed. There should be auto compensation for that anyway.

I hope this post gives you some food for thought! It works for me.

Rats. Several good prints and J1 drops the bomb. I changed filament brand and all is well again. This is a bit nuts.

This is my first printer (out of 12 over 7 years) that has an all metal hot end. That’s saying something to me, but don’t know what. PTFE tubes in nozzles “grease the way” for filament. I may need to learn new rules here about high temp hot ends.

Search “pros and cons of all metal hot ends”. Pretty much tells the story. Don’t need to repeat here. Sorry guys and gals… The news doesn’t get better…

Last words from me: Now printing with my “problem” Overture PLA. No extruder stalls. print is beautiful. 5 deg C above mfg. recommended high. retract OFF (with no stringing) and flow set back to 90% PLA can be printed, but way fussy. It’s all due to the 300C all metal hot end. Problems come with the teritory. Will vary PLA brand to brand and a half dozen other variables.

And now the rest of the story (Paul Harvey)…

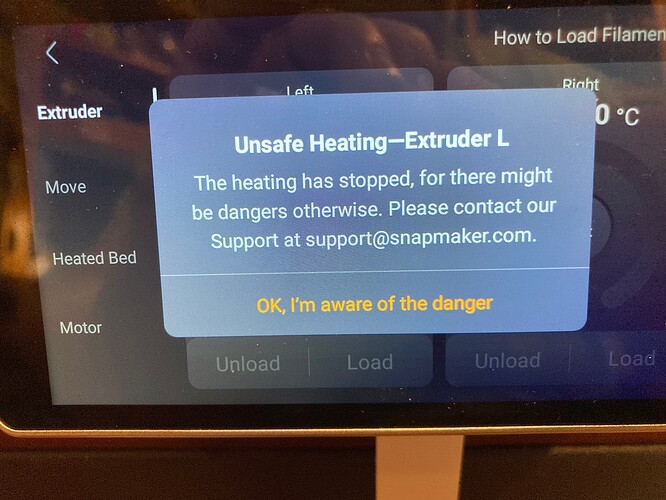

Left extruder temperature control failed completely, middle of a print Failed “OFF” so no damage but generated an

error message. I had turned off filament flow detector as it was extremely erratic, stopping prints when there was no flow problem. Print was going fine but then temperature control went off.

Sent report and log files to Snapmaker support but received lame excuse of understaffed and time off (Chinese New Year?) Anycase, dead in water for now.

Could unstable temperature control be the issue all along? I assumed nozzle temp problems from the beginning. Will see when I hear back from support. I expect I need a new nozzle module??