In the three weeks that I have had my A350, I have been a frequent consumer of these forums. The different posts on getting the bed level, using a glass printing surface, the reason for the ‘bump’ in the Y-axis, and several other topics have been of great assistance. There are far too many different contributors whose posts have been helpful to list them so please accept this as my ‘Thank You’ to the community!

A solution to this particular issue seems to elude me though. Having nearly exhausted the SM filament that came with the printer I purchased some PETG to begin using. I want to learn how to use this filament because living in Arizona, it gets hot outside. I have several ideas in my mind for uses for parts in the garage, in the cars, on the boat, etc. and PLA probably won’t cut it there.

This problem seems to only present itself when printing larger parts; parts with a side dimension of greater than 60mm or so. Bed leveling is good and I can print a very good first layer. The challenge is when printing the skin for the bottom of the part filament begins to build-up on the nozzle. Eventually, the skin begins to look like it is growing hair. As the nozzle passes over the ‘hairy’ areas it collects even faster on the nozzle which seems to produce more hair until eventually, a giant blob of plastic is dropped either somewhere on the print or, if I’m lucky, grabbed by the side of the print and falls off the edge…

So, what have I tried so far… I’ve adjusted the printing temperature, retraction distance, and retraction speed. Currently, I’m printing at 230 degrees, 1.5mm retraction at 60mm/s with a printing speed of 40mm/s. I noticed that when printing PETG at 220 or below the layers don’t adhere together well. Anything above 230 and the ‘hair’ is out of control. With my latest print, 174mm edge dimensions, the second skin was growing a lot of hair. I paused the print, cleaned off the nozzle, lowered the nozzle temp to 225, then continued printing. I didn’t see much difference, still getting plastic accumulating on the nozzle and, the last few layers of the print did not adhere well. The top surface skin layer did poorly.

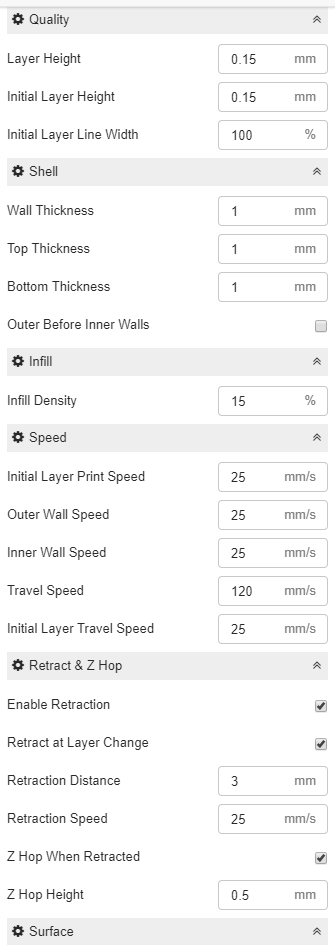

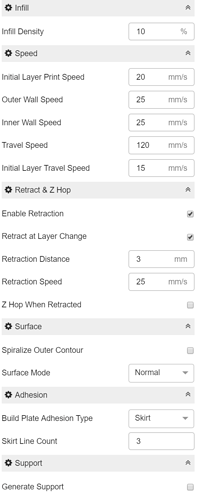

I have since downloaded Cura and configured it for use with the A350. This does give me much more granular control of the print settings but before I begin blindly changing what I ‘think’ may help I wanted to ask for advice. The walls of the print look good, printed at 40mm/s. Should I speed up the skin printing speed keeping the temp at 230? 230 seems to get the best layer adhesion with the least amount of ‘hair’.

I apologize for the lengthy post and I appreciate your time!