Yes I saw it, thank you. It was too late however. I had already started using the one on thingiverse as a model… Ah yes I try to avoid removing the hotend as much as I can. Luckily the bracket for mounting the fanduct has got hinges so I hope I will not run into too much trouble when I need to remove the hotend…

With the original cooling nozzle? Indeed. With the double-5015 nozzle however I would interpret alfrank’s picture as “sufficient cooling”.

But I am keen to see your solution anyway ![]()

Yes I agree about alfranks green pyramid looking good, but i’m not convinced that 1-way cooling can work well in all situations. Sometime you only want to cool the part a little bit and depending on the orientation of the part, you could (will) get results more like the white pyramid…

My version fits on the printer so it might work in its current state but I have not tested the airflow/results. It will take a few weeks for my 4020 fans to arrive from China =(

If you Print a sphere or bowl or some rectangular the side who is away from blower is bad, i need to finish my ring cooler but have too much work here ![]()

Maybe optimize the outputs a bit more towards the print bed…?

Yes, I will optimize the outputs and also reposition the arms to compensate for the nozzle not being in the center of the heatingblock. There will be another version soon =)

Looks good, could really work…

Is there a suggested print orientation?

Yes. I printed it on the J1 with these settings:

Orientation: airchannels/arms pointing upwards

Layerheight: 0.2

Tree supports

support z-distance 0.4

brim (probably not necessary but why not)

Linear advance 0.1

support blockers for all holes and the airchannels…

There is a 3mf file to download with the support blockers added…

It looks like I missed putting support blocker for one of the holes. Not a big deal but I have now updated the 3mf file…

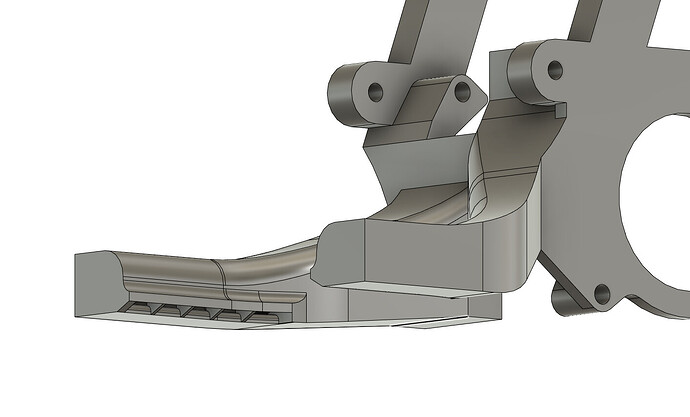

Today, I made some changes to the fanduct. I also noticed that there is another fanduct on thingiverse for dual 5015 fans…

I tried to print your fan duct. Don’t work. He broke all the time.

Now I tried other direction. I use support PVA.

Cant find M Parts on Thingi

What print speed do you use? I use 125mm/s and he need 4 Hours + says Cura

Do you make some changes on the fan duct? Or only the on the multi part. The Multi is mean other material for the gasket?

Kindly Regards

Ok. I upload new versions sometimes. Maybe you have a old/bad version…

I printed the fanduct with these settings:

Orientation: airchannels/arms pointing upwards

Layerheight: 0.2

Tree supports

support z-distance 0.4

brim

support blockers for all holes and the airchannels.

Speed 200 mm/s

infill speed 200 mm/s

travel speed 150 mm/s =)

I printed lots of diffeent variations of the fanduct. None of them failed… Maybe you have too high retraction distance? I lowered it to 2 mm…

In the new version I have raised the height a little. I have shortened the arms and also repositioned them to align the nozzle more acurate in the center.

This new version is currently only multicolor and normal. No gasket version…

Yes I deleted the M parts and replaced them with the .3mf file

Thanks for help. I try now the new version without the gasket.

Is the gasket need to print too on this version

No problem! There is no need for gasket on this version… Just fanduct.stl. You might want to download it again though. I just made a little change and uploaded a new version =)

AAAh, new again, i donload the fan duct today morning, now its only the blue part new?

i print the version without the blue part.

lol ![]()

![]()

i use 1 to 1,5mm retract

speed on 125

rattleling, clogging all that stuff…

i need to do some of your fixes about the clogging and hope support helps too, need new heads. the rattle comes from the heads but cant find anything.

we will see, hope they give me a support with my printer

Ok that doesn’t sound too good. Hope that snapmaker support will help you with whatever is needed to fix the problems.

Yes i forgot to add the blue part earlier. I think it could be good for rigidity. Especially when printing with high speed…