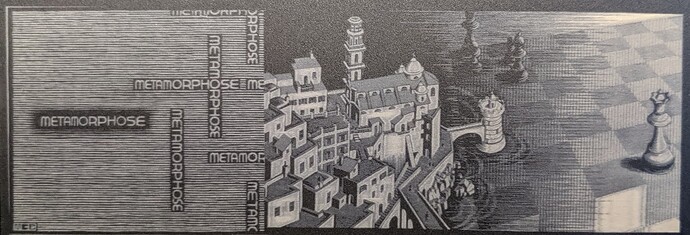

I did engraving with the 2W IR on the black acrylic that came as sample material with the Snapmaker. It yields extremely nice results (The image here is only 3.2 cm high):

But I had my frustrations and learnings. From that, here would be my quick’n’dirty guide how to get to the right settings:

- The 2W has a beautifully tiny focus point, so line spacing should/can be 0.05 mm

- Do a test engrave pattern with speed 1000 mm/min, Constant Power On and a power series in 5% steps - from this determine min/max power to have the acrylic still black and fully white

- Do another test pattern at 1000 mm/min, constant power on, ranging from determined min power to 16% power in 1% steps - this is to determine the lowest power your laser module makes an impact. For details on why, read the first thread I linked above. The % power that just starts to make your acrylic white we need at a later step - I’ll refer to it as ModuleMin%.

- Now you can set up your photo job (Lightburn):

- Make sure the device uses Inline mode (Device settings)

- Line Spacing: 0.05 mm

- Method: Greyscale (this is different from Greyscale in Luban - what Lightburn offers as greyscale is not existing in Luban)

- Min power: The value you determined from the test patterns - the maximum power that still leaves the acrylic black

- Max power: The value you determined from the test patterns - the lowest power that gets your acrylic fully white

- Constant Power OFF

- Image inverted

- Create the GCode, and add the line

M2000 L24 Pxx, where xx is 255 * ModuleMin% / 100. The line goes in front of the first G1-command.

This will result in a high-dpi true greyscale image, which looks awesome.

Unfortunately things are that complicated for two reasons:

- The controller struggles to process the many, many GCode commands involved in engraving a picture. This limits speed. I suggest 1000 mm/min, but perhaps 1500 mm/min might also be OK, I did not yet test.

- The 2W modlue has a lower limit at which power setting it can operate. Snapmaker assumes that this lower limit is 16%, but my module works down to 11%. This causes issues, and the M2000 L24 Pxx-command overrides the Snapmaker limit with what you determined for your own module. The step of determining this value needs only be done once, it does not depend on the material used.