I am currently finding my way into laser-engraving black acrylic with the 2W IR laser. Using a few test patterns, I established that at a speed of 10000 mm/min, a nice and fine line spacing of 0.05 mm, and using laser power between 10% and 40% I get beautiful true greyscale (no dithering or halftone)! So I was very much looking forward to engraving my first image. Lightburn produced a fine file working with inline power for each dot - so basically a loooong sequence of 0.05 mm movements with a given laser power. And basically the file works - I do get greyscale - but not the one I intended, but a too intensly lasered one - reason: The laser creeps at a speed far below 10000 mm/min across the workpiece! The touchscreen shows that the target speed is 10000 mm/min, but the de facto speed is less than half of it I’d guess. My main assumption: The GCode-processing eats up too much time, and the controller just hasn’t it in itself to process 0.05 mm spaced inline power commands…

I mean: obvious solution is to find the sweet spot that the controller can handle - but this will “compress” the achievable power range to 10% - 20% or so, which may mean loosing dynamic range… Still, I’ll try this and keep you posted!

Anyone any insights that may help me?

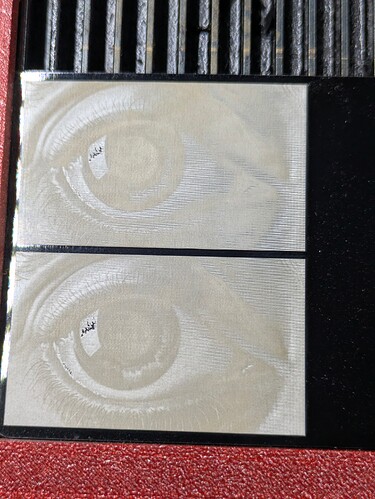

Btw. here the test patterns, which show how nice a greyscale you can have! Please note: This is not in any way dithering or halftone - varying the laser power causes the whitening to be gradually stronger, but within a square of the test pattern the laser holds the same power for the entire scan time.