Hello,

I changed the nozzle from 0.4 to 0.6.

Easy process, all went well.

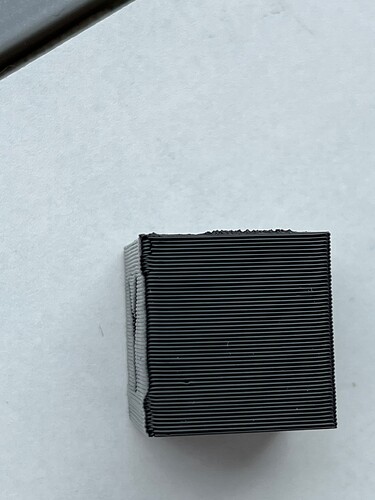

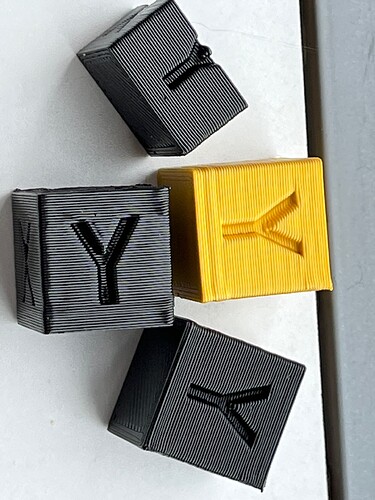

I am doing a calibration cube test and below are the results which are kind of wierd.

I did:

- extruder calibration

- change cura extruder size

- using default settings with 0.4 or 0.3mm layer

- used 2 different filament

- bed calibration

- try ± 0.05mm adjustment in case.

- try couple of print speed.

If you look closely.

First layer is good

The layer where the Y is printed seems homogeneous. But the layer at the bottom and top of the y are larger, but it seems only for the Y side.

The other sides are ok.

I have 3 top and bottom layer defined in cura, however the count of the dodgy layer is more around 5, so probably not related to the settings.

Anything I could try ?

Any idea what could be the issue here?

Thanks