- Generate Laser file for the rotary module. (SVG, DXF, and IMG are supported)

- Generate CNC file for the rotary module. (SVG, DXF, IMG are supported)

- STL file is supported

- Rotation (For simple models without hollowing)

- Linakge (Suitable for complex, hollow models)

- STL file is supported

Laser sector workfolw

- Switch to Laser 4-axis

- Input the size, length and the diameter of the material.

- Import the file, Choolse a processing mode, Adjust the size and position

- Adjust the toolpath and preview it

- Generate G-code file and export it to USB stick or send to the machine via -Fi.

CNC section workflow

-

STEP 1 Switch to CNC 4-axis

-

STEP 2 Import the file and adjust the size, choose the position of the model.

- Placement Face

- Select the chucking surface that will align one of the model’s faces

- Image Density(Adjust the sharpness of the preview image)

Image Density = 1

Image Density = 5

- Image Density(Adjust the sharpness of the preview image)

-

STEP 3 Select the CNC bit and adjust the toolpath parameter.

- Slice Mode

- Rotation, the right one(For simple models without hollowing)

- Linakge, the left one (Suitable for complex, hollow models)

- Step Down

- The depth of each carving step

- Slice Mode

-

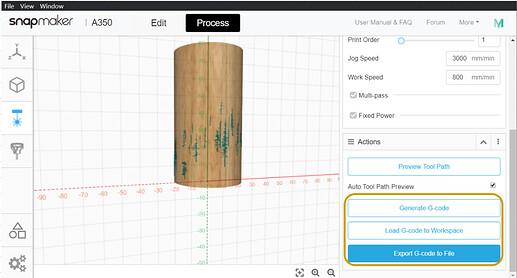

STEP 4 Generate the toolpath and preview it

-

STEP 5 Generate and export G-code file

-

Generate Laser file for the rotary module. (SVG, DXF, and IMG are supported)

-

Generate CNC file for the rotary module. (SVG, DXF, IMG are supported)

- STL file is supported

- Rotation (For simple models without hollowing)

- Linakge (Suitable for complex, hollow models)

- STL file is supported