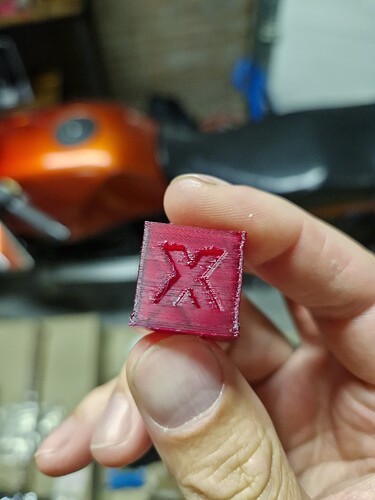

Looks like it could be one of a few things;

1: Wet filament. As the moisture in the filament boils off, it pops and creates voids and strings. Get a filament dryer or food dehydrator and dry it for 12 hours.

2: Underextrusion. Either uncalibrated, too low heat, printing too fast, etc. Though it usually manifests in longer, thin lines than random bubbles.

3: Bad filament. Could just simply be a crap roll of filament. Do you have another spool of the same material to test? It could have bubbles, inconsistent thickness, or contaminants in the filament.

4: Partial clog. On the slow brim and first layer, it could be slow enough that enough plastic is managing to get around the clog, however, the faster subsequent layers can’t keep up and gives more spurts (i.e. builds pressure behind the clog, then releases) giving a bit more inconsistent than the underextrusion of above.

5: Damaged nozzle. Check the tip of your nozzle for wear and damage. If you’ve run a brass nozzle for a long time, especially with any non-standard filament such as wood fill, carbon, glow, etc. the tip could be warn and instead of a flat tip smoothing the plastic, it could just be gently ripping up the top edges.

I would do a cold pull, test a different spool of the same filament, or even a spool of completely different filament as a test. I’m leaning more toward wet filament, but I also do not know the layer height you’re printing or any other settings. Also since you mentioned it’s ABS, make sure there’s no stray drafts or anything, it could be cooling too quick and the nozzle simply tearing it up. However the upper part looks very underextruded. Without a lot of testing, it’s really hard to tell what’s going on.

You mention infill being set at 20%, you haven’t hit the infill portion yet, you’re still laying the base layers. What is your 3D printing experience level?