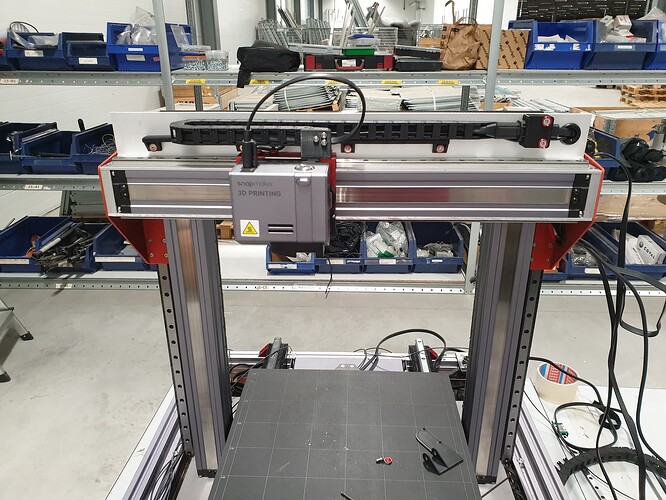

Hi fellow Snapmaker owners, after having my snapmaker 2.0 A350 for a while, i have noticed some things that I’d like to change, and I thought some of you might be interested in the modifications I’ve made and would like to see them. So this is going to by my build blog for my A350T!

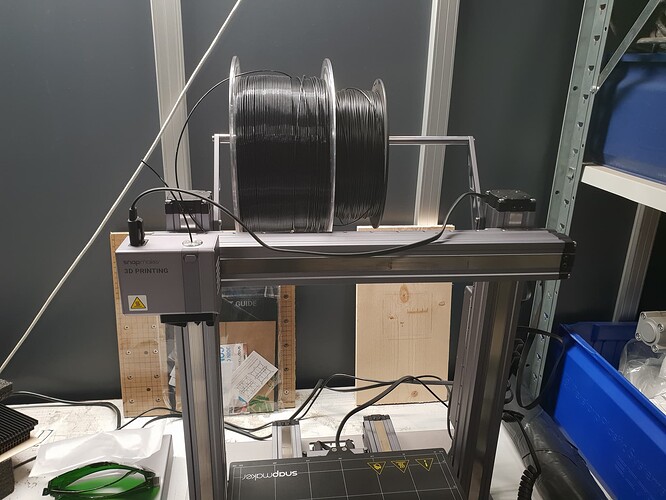

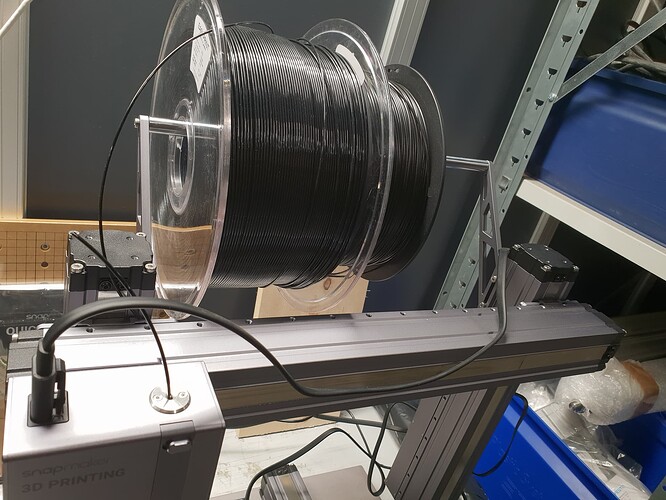

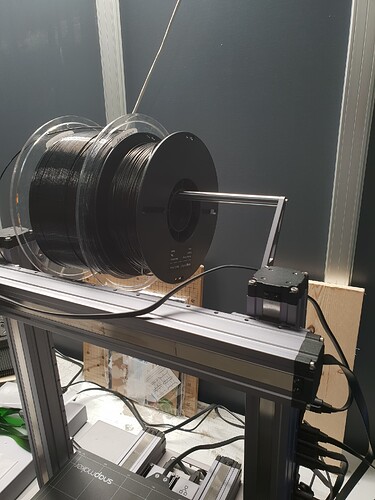

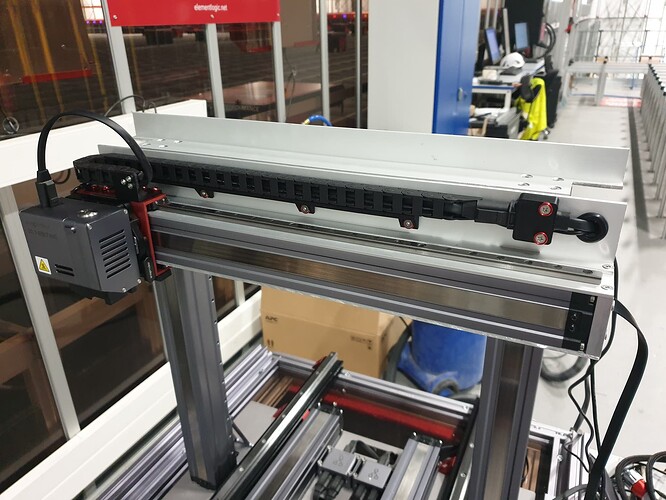

so the very first mod I did was a large rail to support multiple rolls of filament. this worked well apart from it being not very user friendly when changing the rolls:

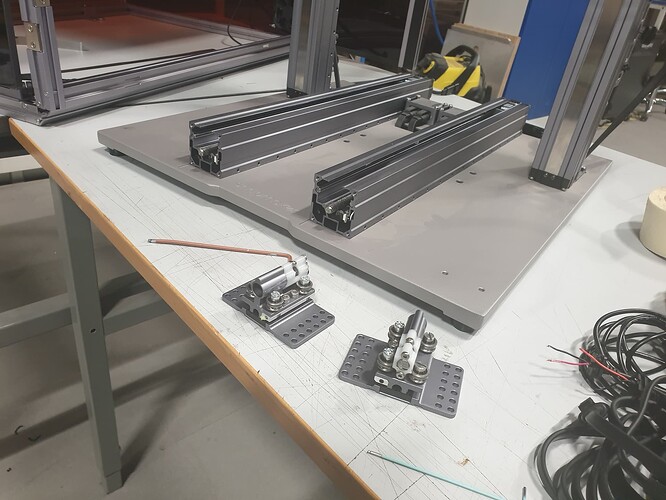

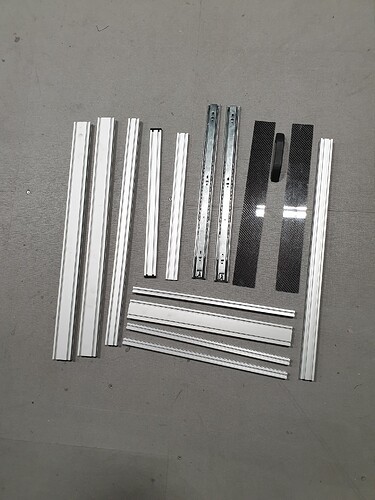

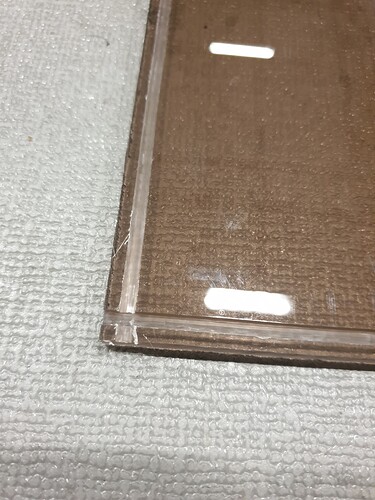

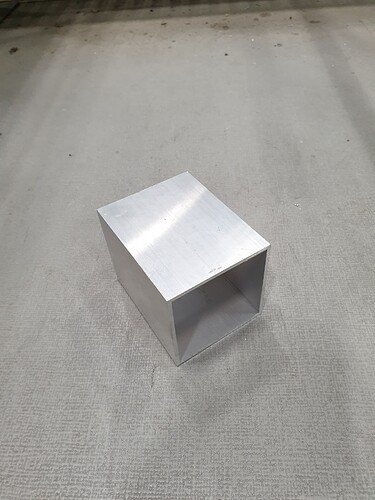

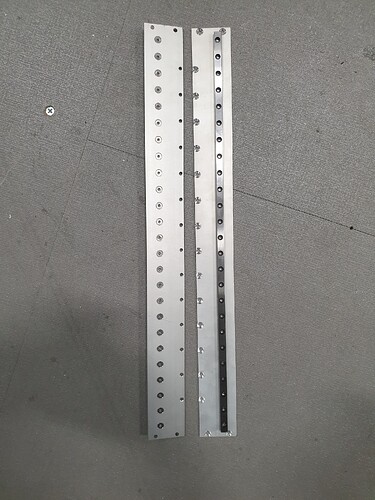

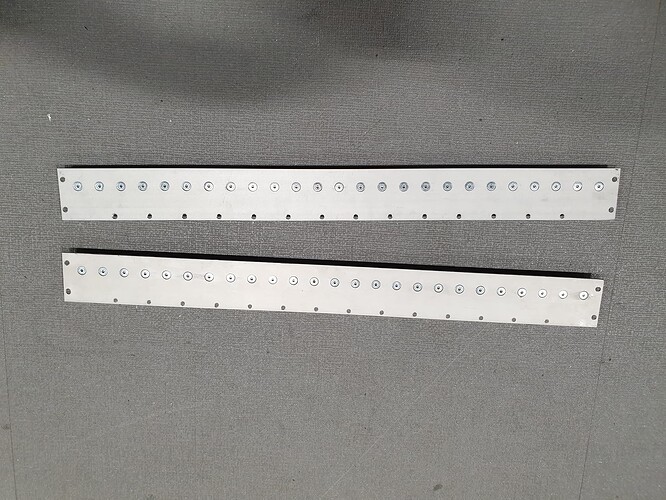

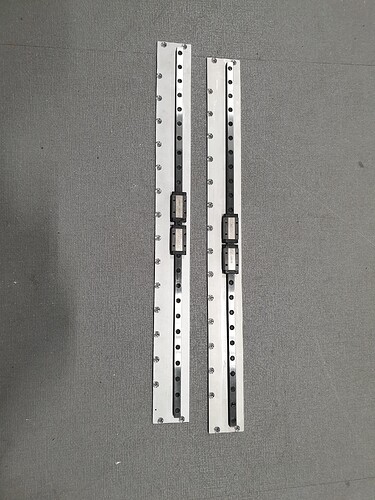

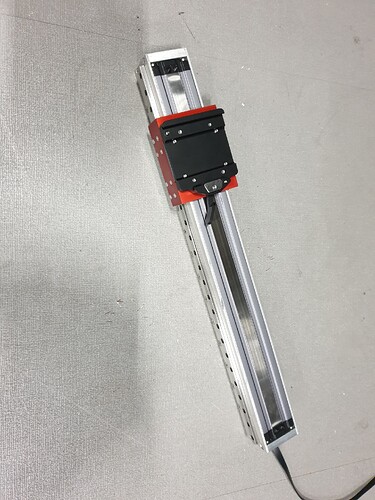

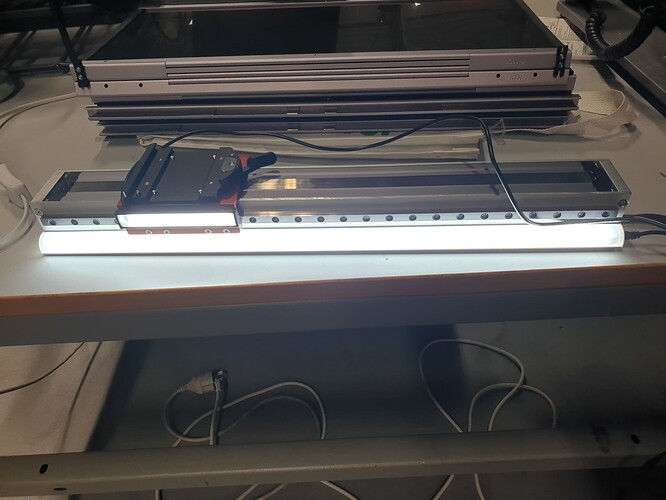

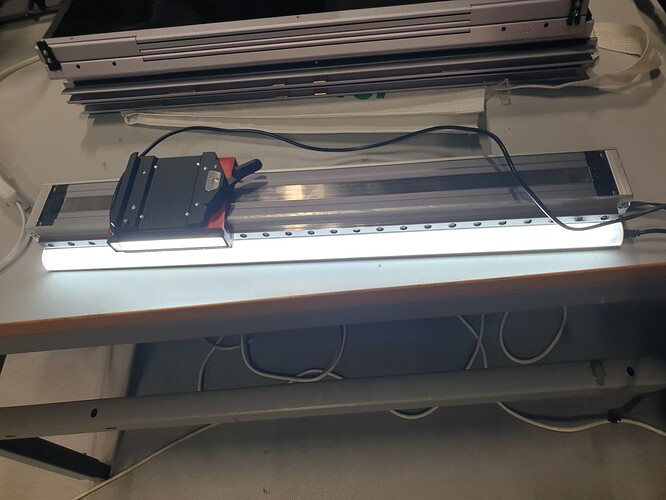

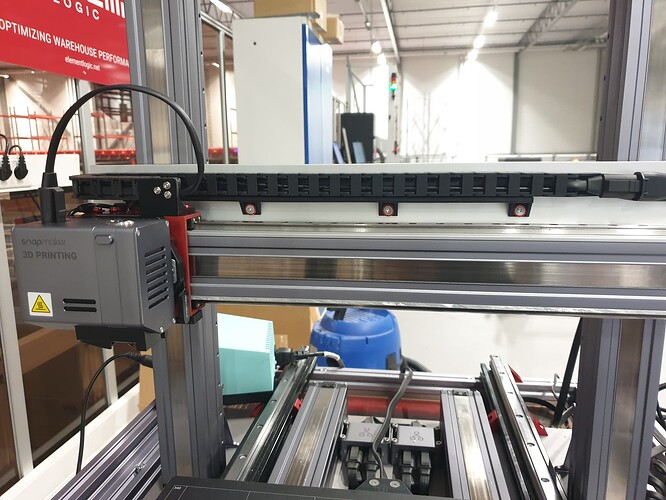

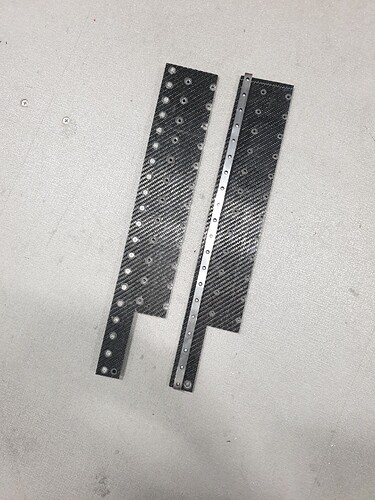

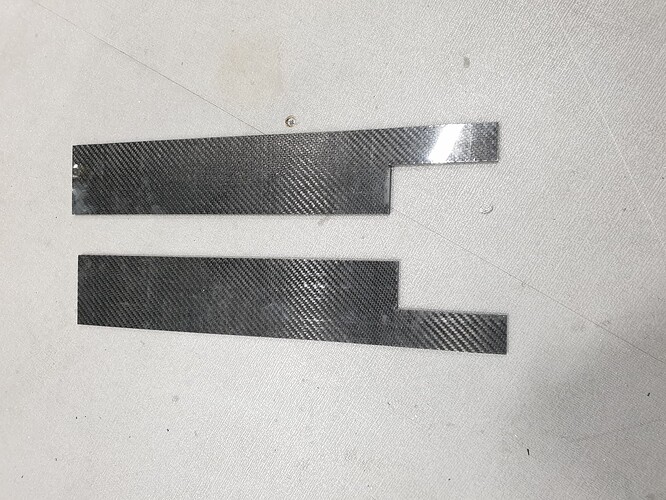

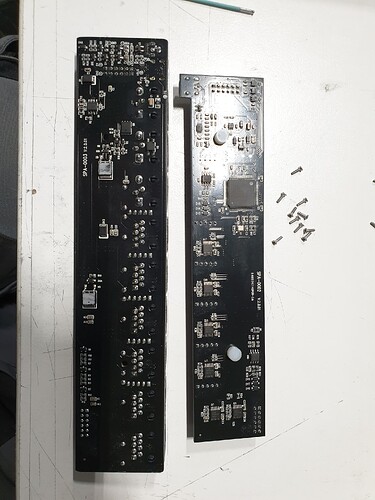

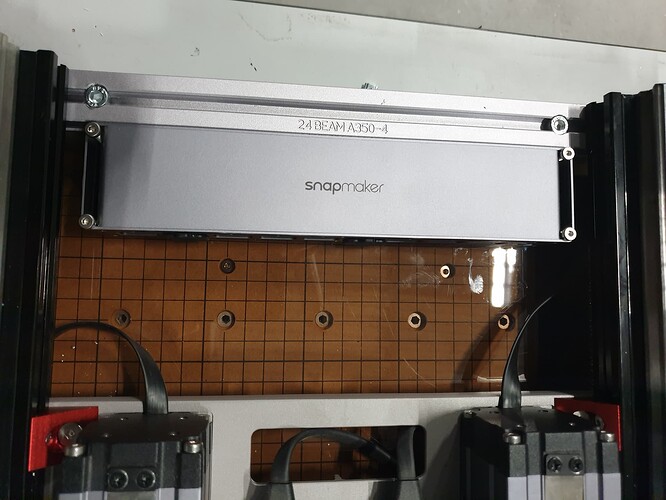

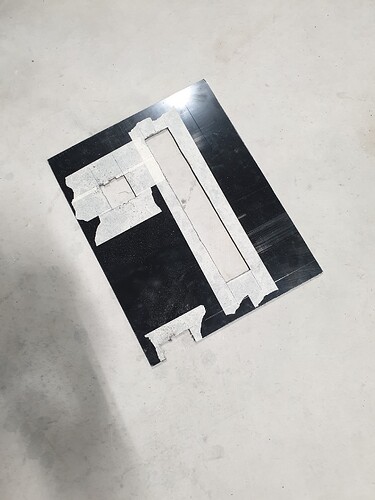

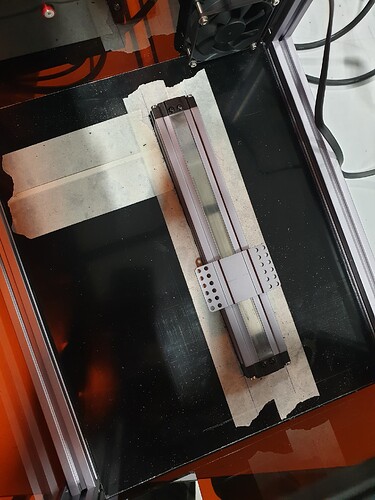

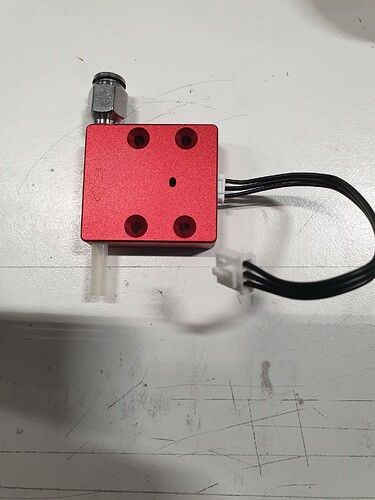

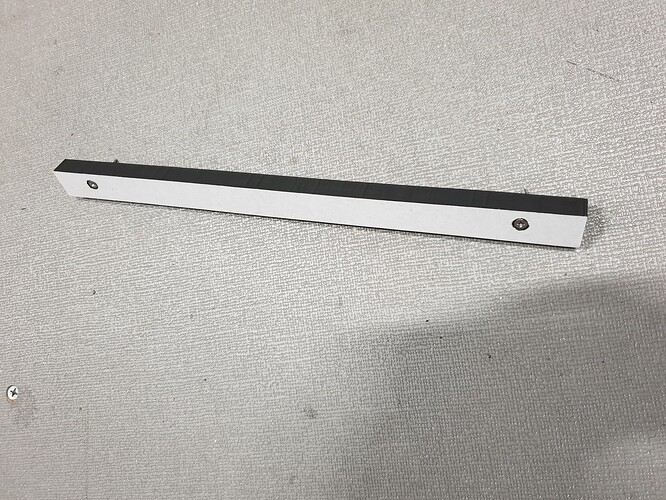

But shortly after that mod I got the dreaded loose linear actuator issue. I took apart the rails to try and improve the stability and destroyed the stainless steel dust covers in the process. luckily support was able to send me new covers and I finally fixed the rails:

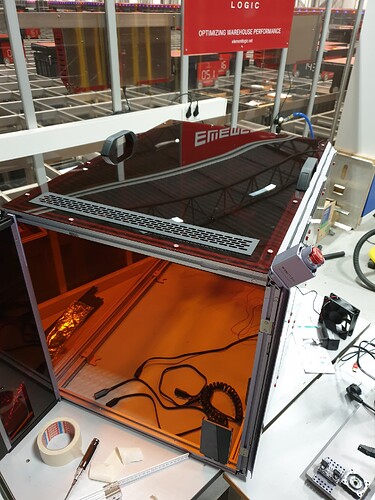

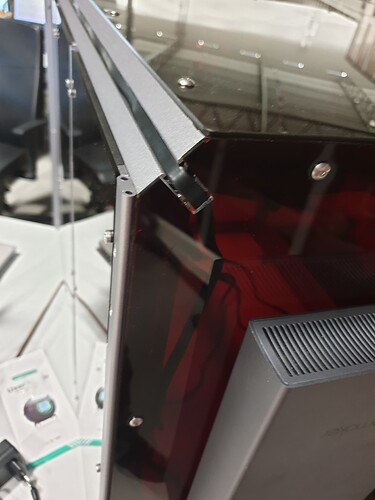

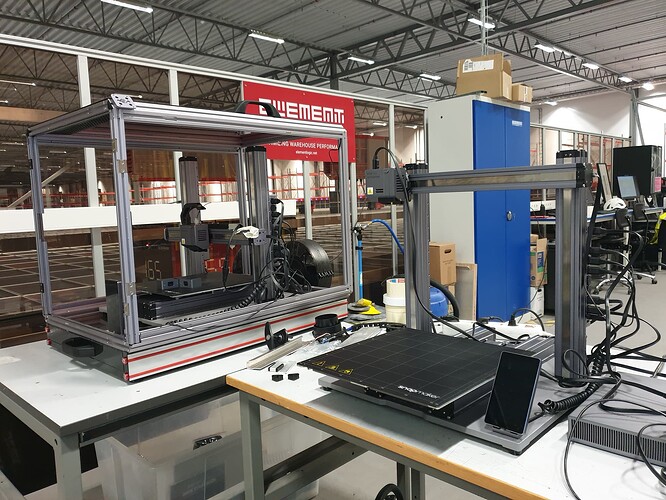

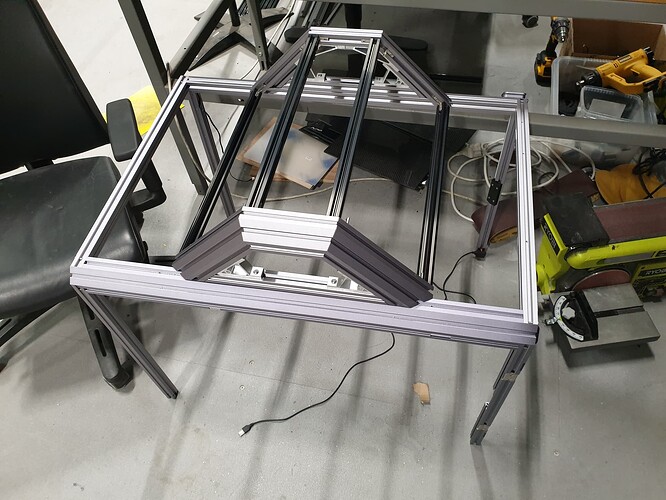

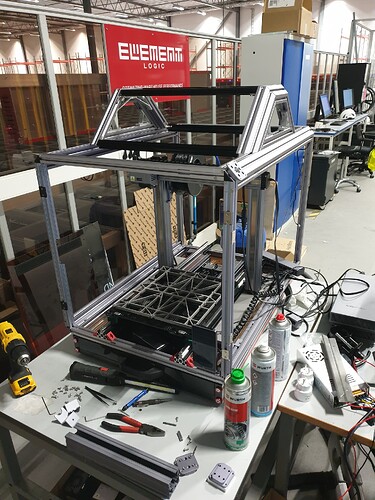

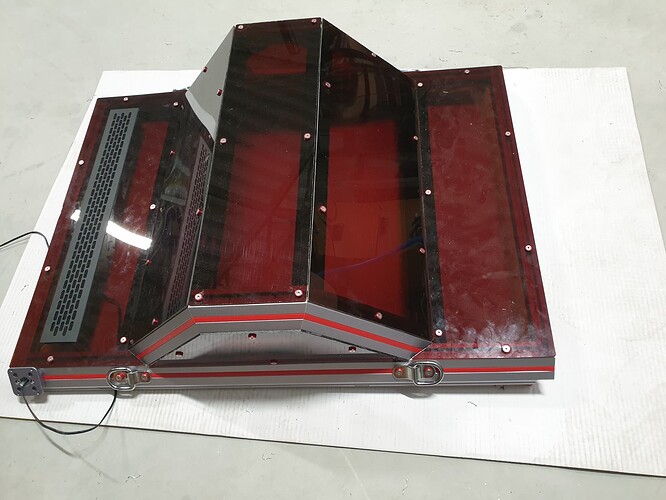

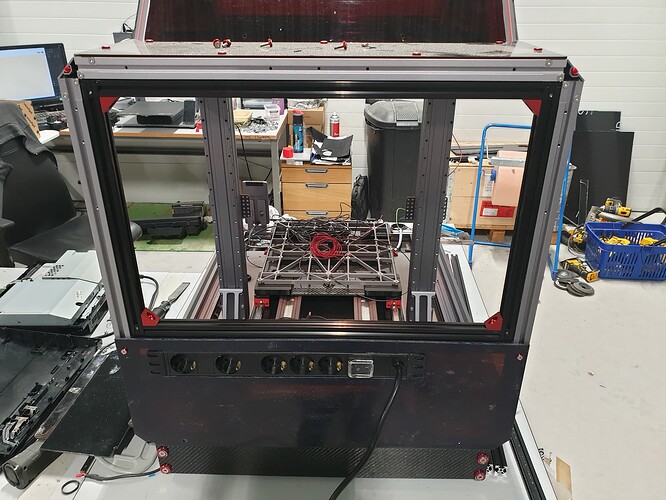

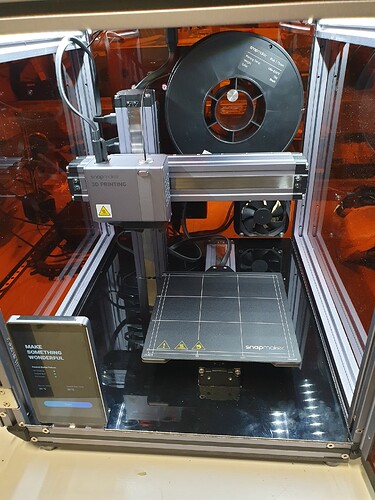

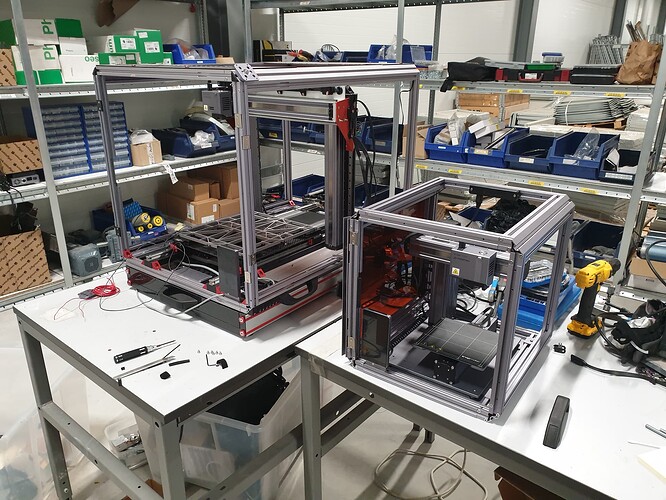

I also got the enclosure which was way bigger than I had expected, the A350 suddenly become a lot more complicated when moving:

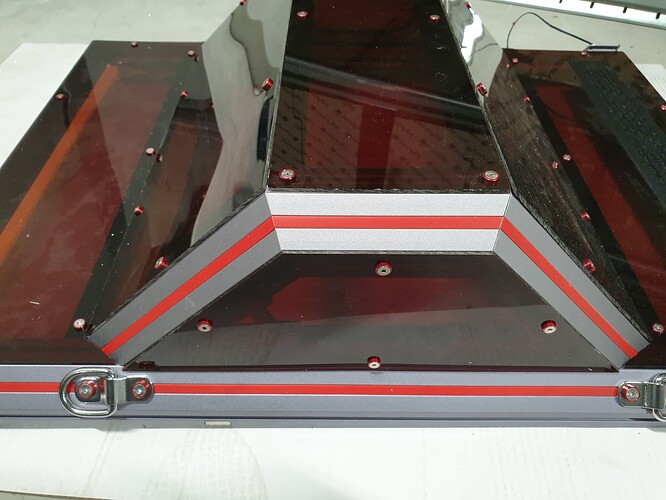

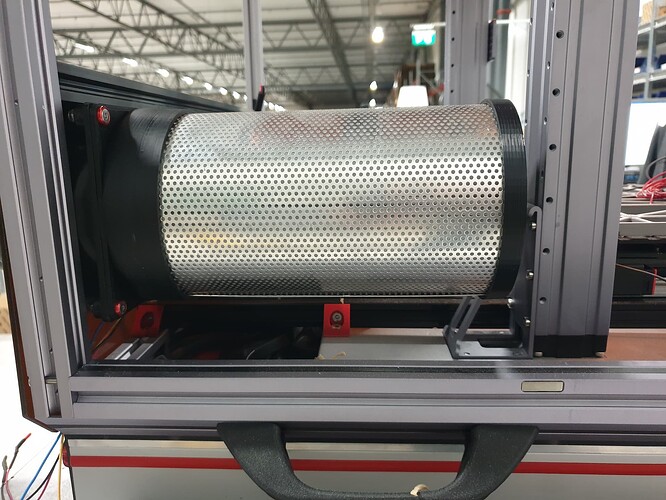

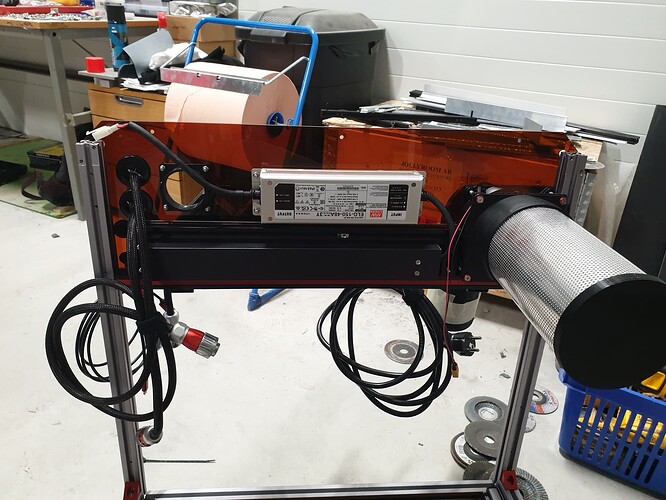

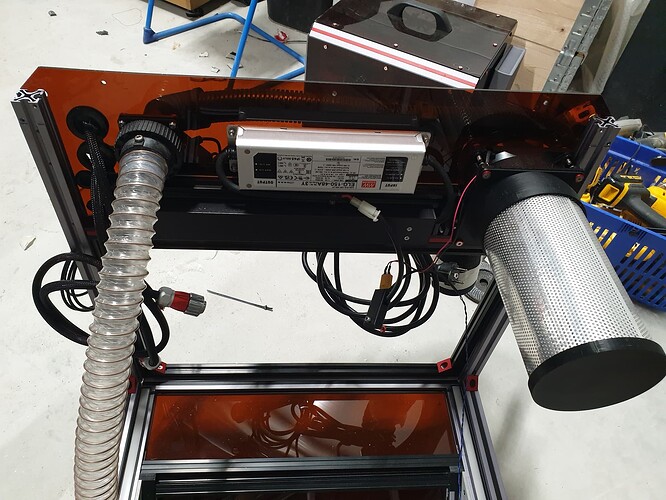

But I realised that the exhaust system for the enclosure didn’t have anywhere to take in air so i decided to put a filtered vent on the top at the front so air is drawn in and then blown out the back. I also added some details to the screws and some handles on the top to make the whole thing easier to move:

I found some very clever person had made some covers for the corners so i printed those off and added them as well:

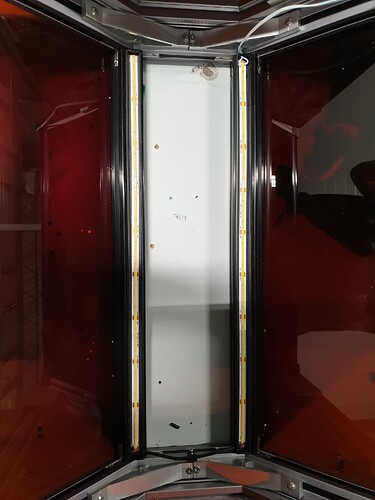

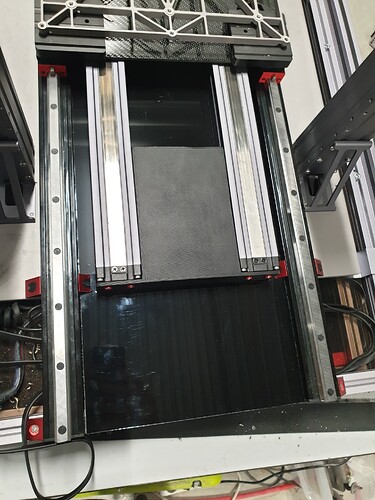

Next I wanted to be able to gain access to the other side of the machine so I started work on a door:

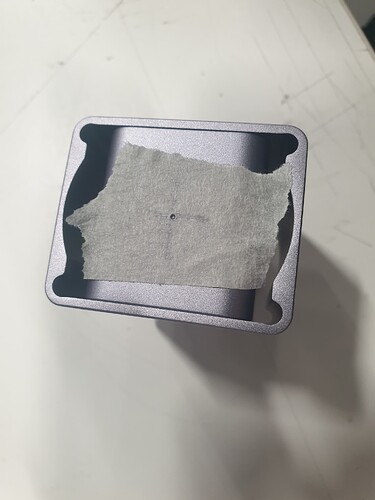

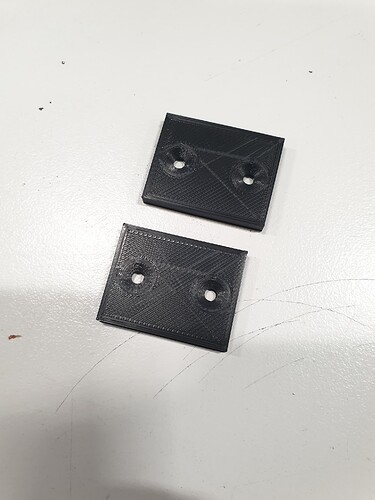

The door needs a locking mechanism so I made that as well:

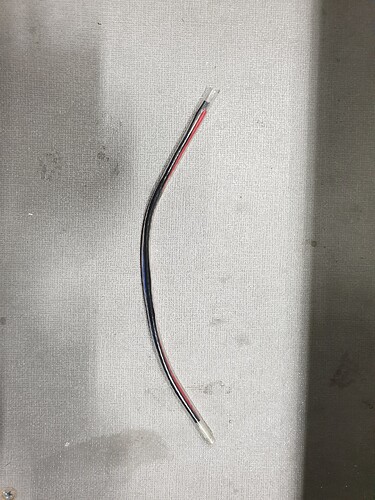

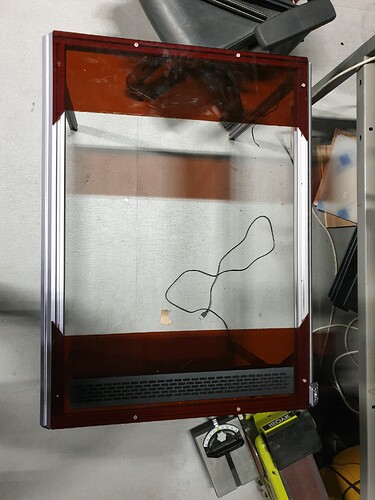

I also didn’t like how the USB socket was at the back. I know the idea is to use wifi, but that isn’t always possible, so I made an extension cable that brought it to the front:

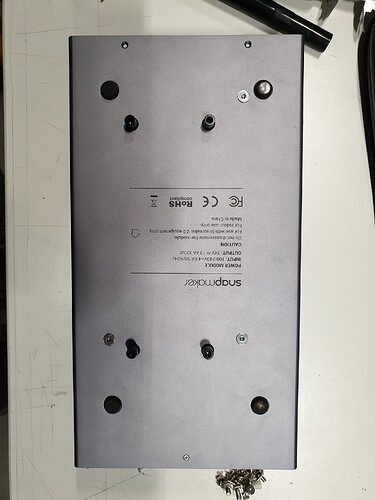

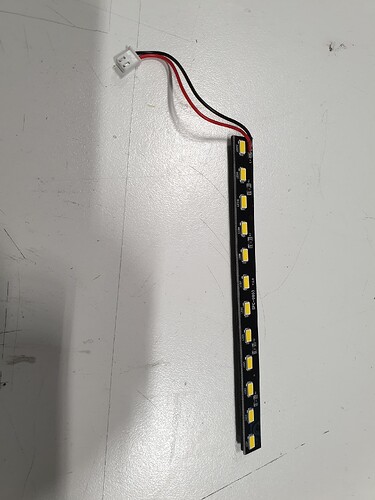

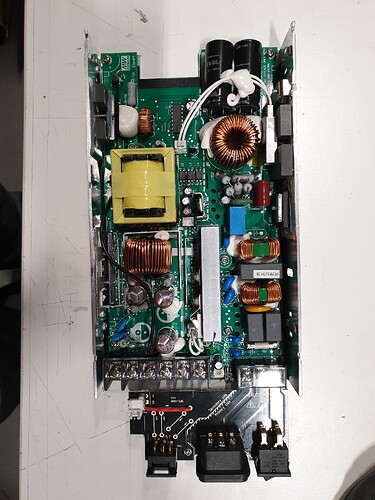

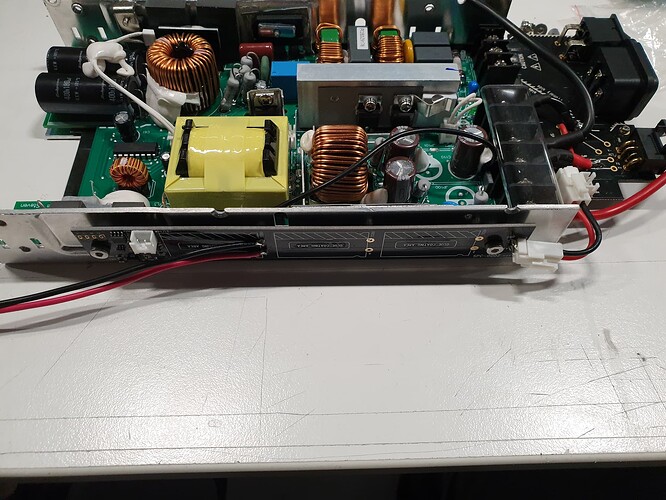

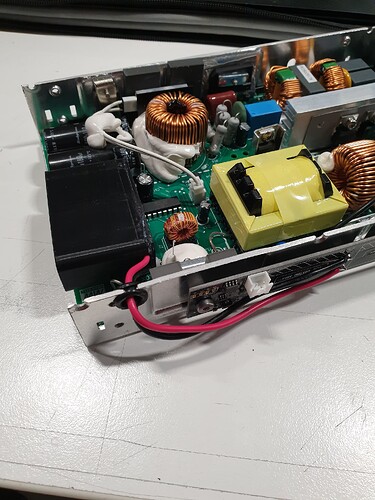

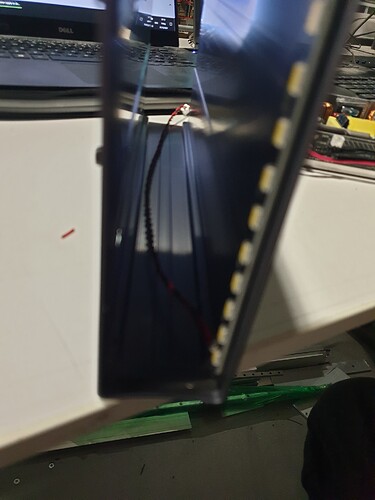

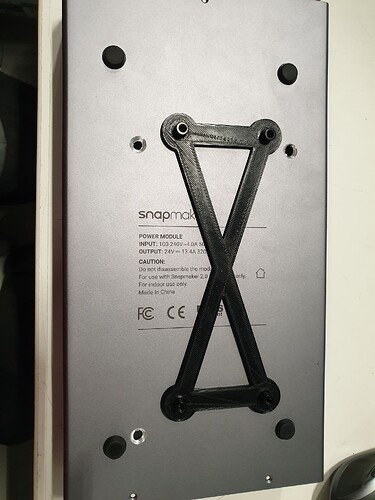

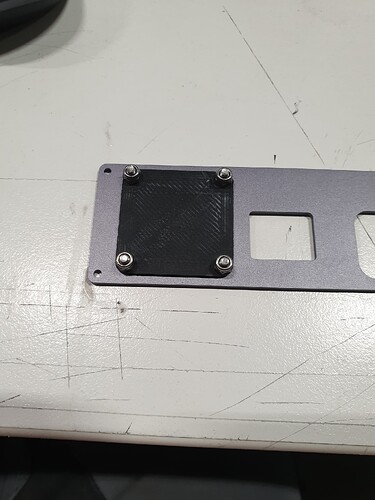

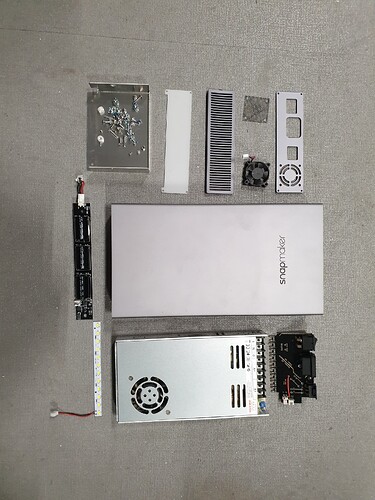

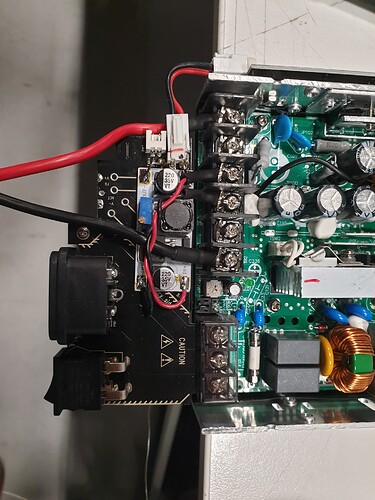

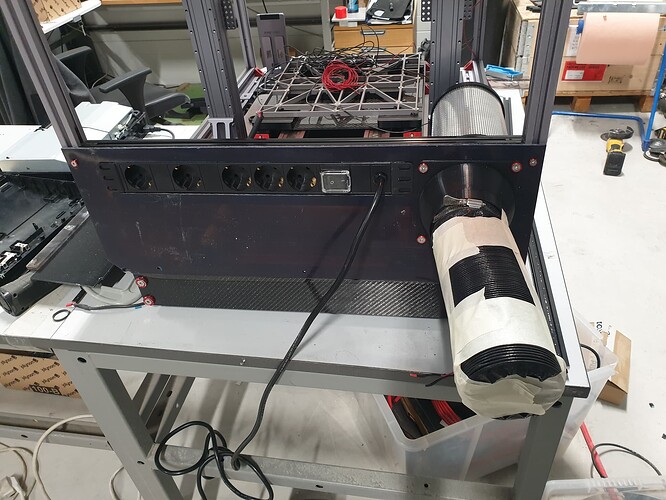

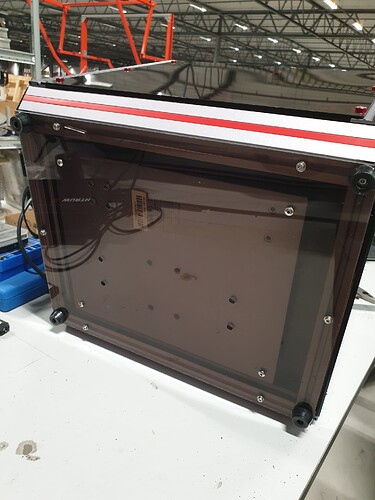

I thought that the power supply was feeling left out, with the enclosure being almost a complete unit apart from the power supply, I decided to mount it on the back window:

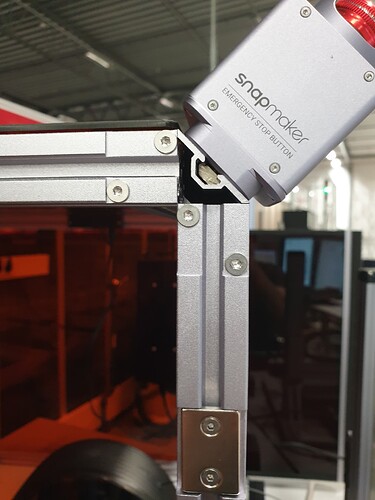

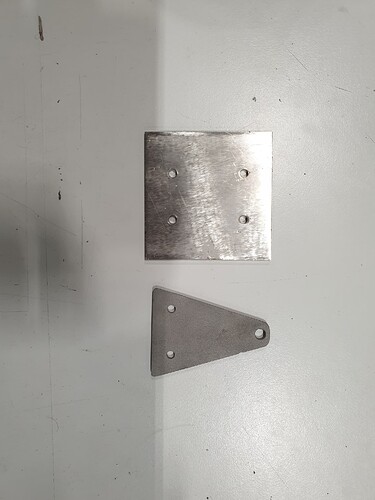

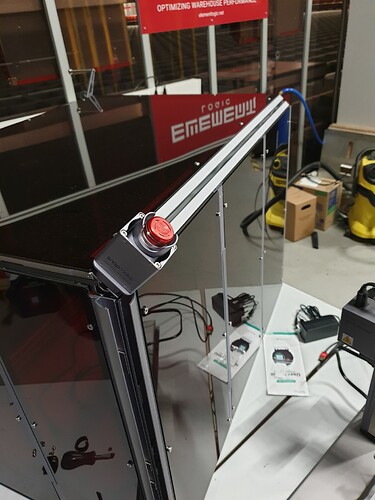

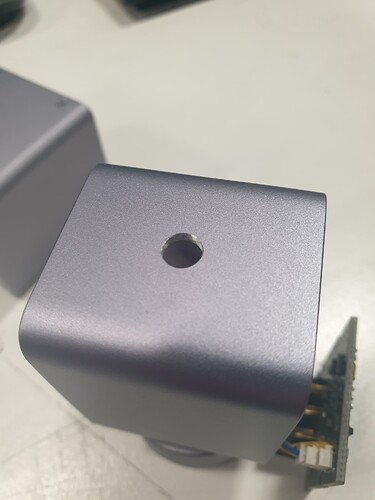

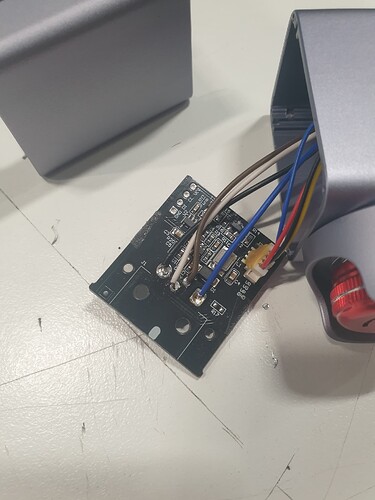

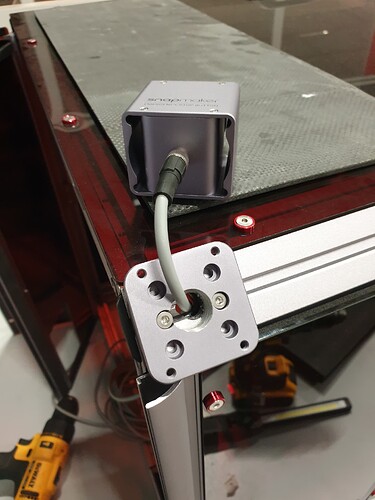

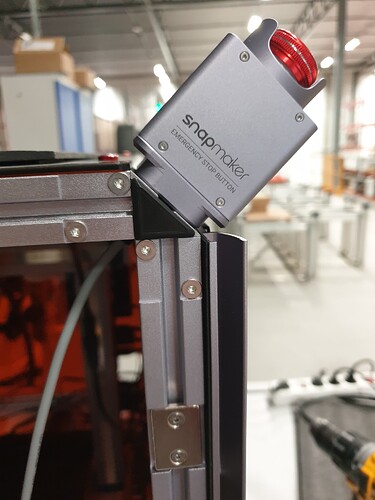

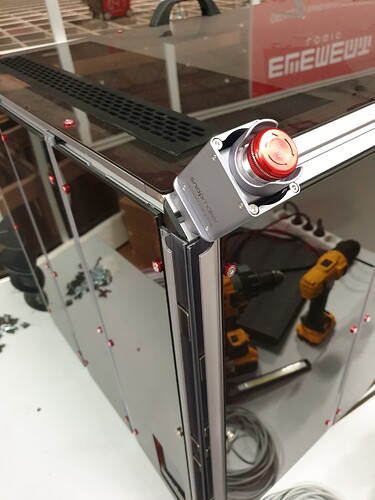

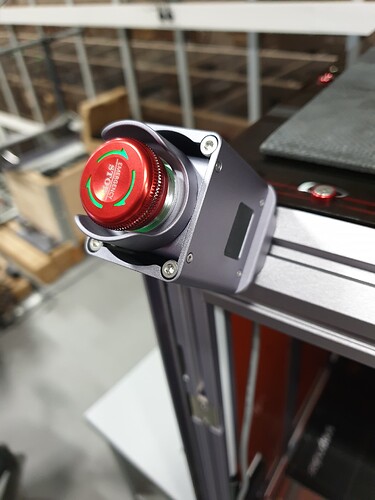

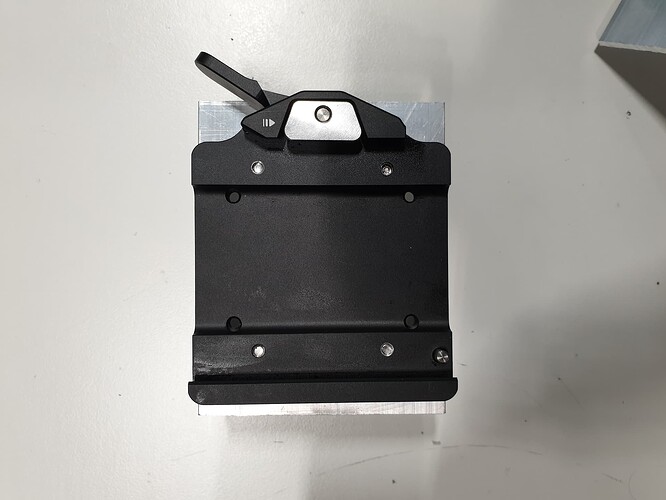

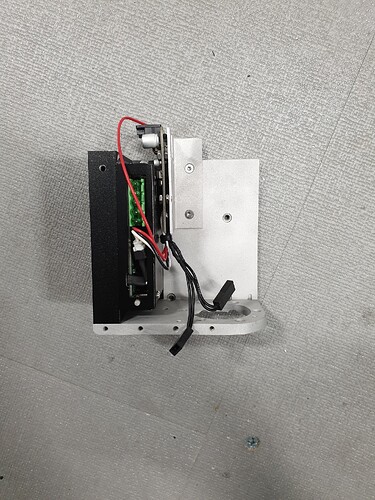

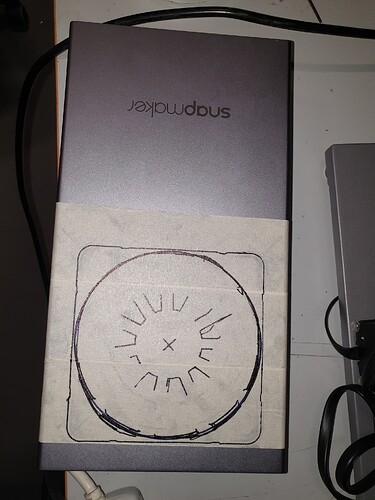

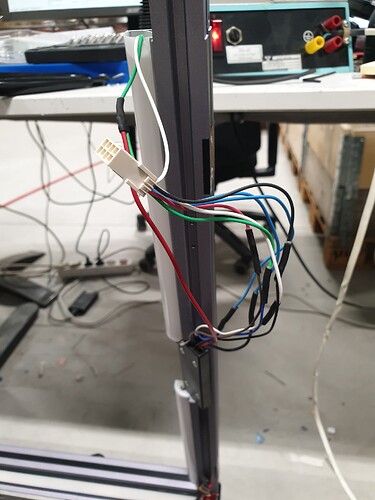

next I decided that I didn’t like how the E stop button had a cable that sat on the outside of the machine so I made some slight modifications so it was a bit neater:

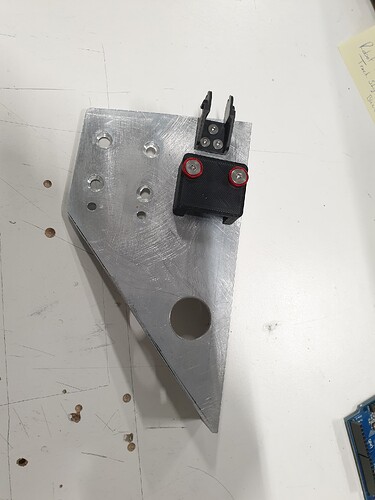

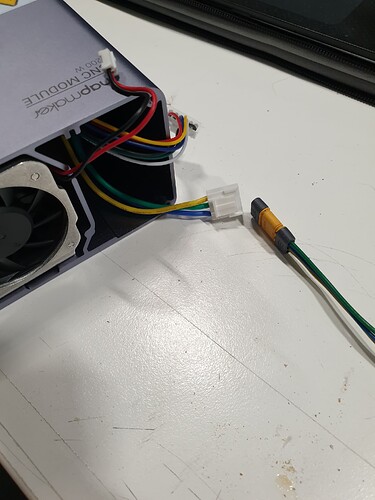

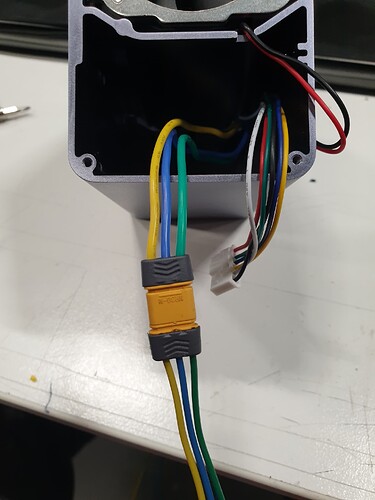

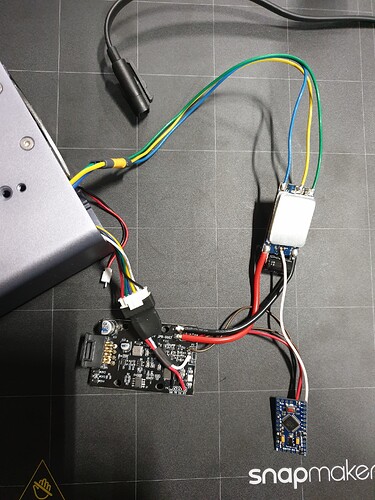

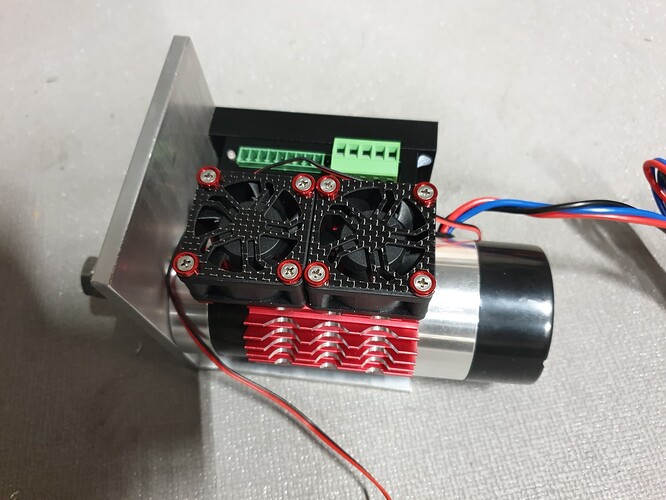

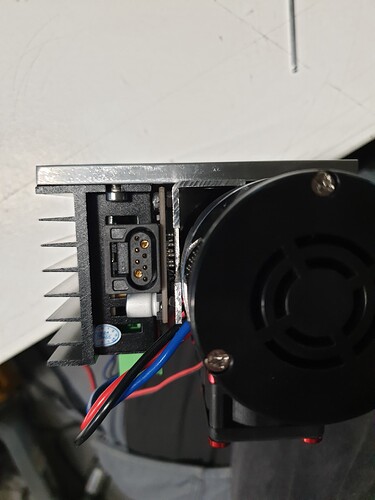

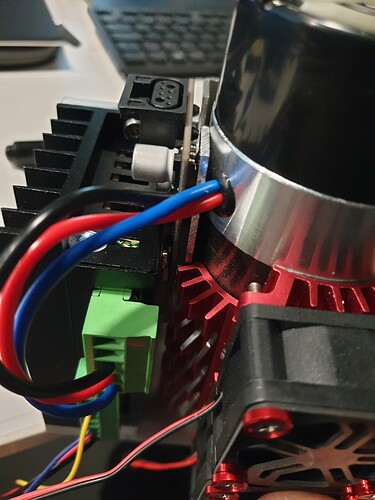

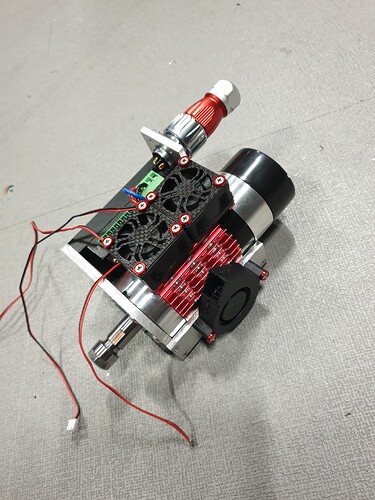

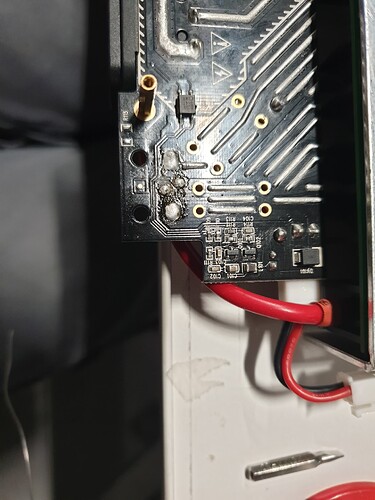

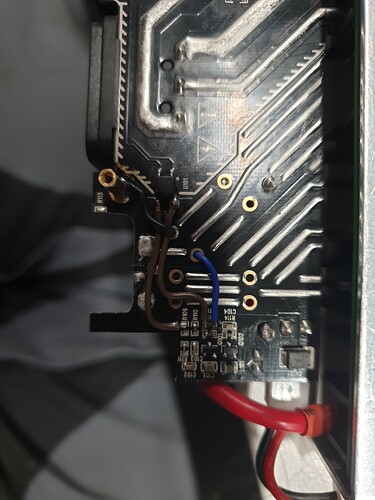

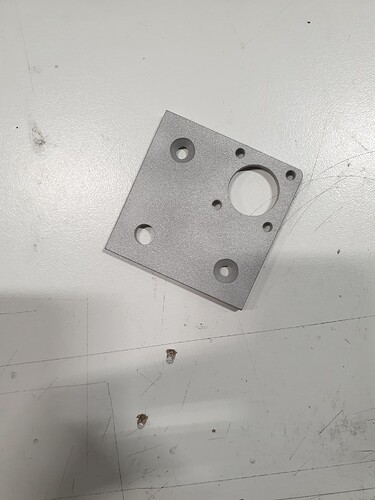

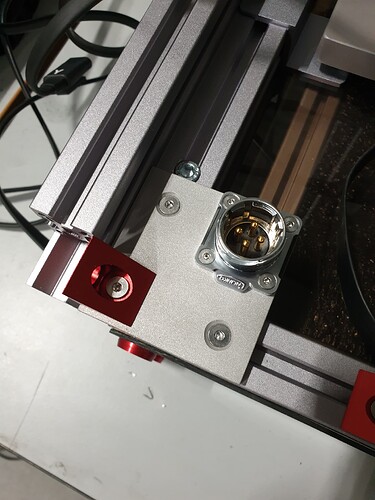

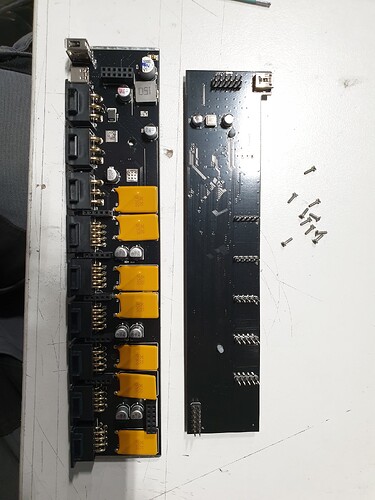

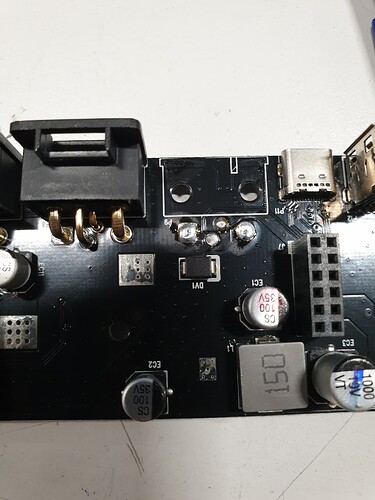

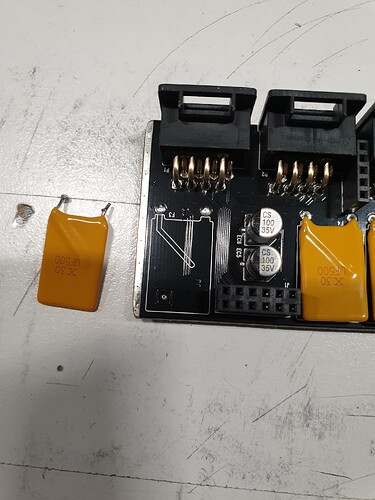

That would have been fine, but unfortunately I am not easy to please, so I decided to make the cable entirely internal with a more aggressive modification:

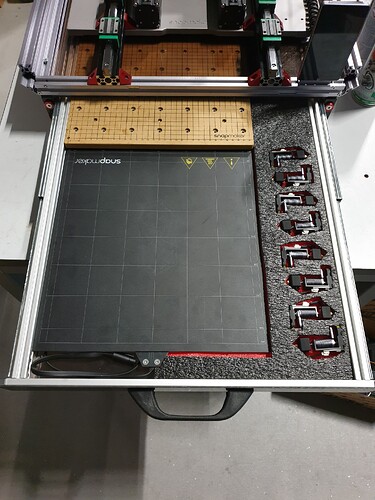

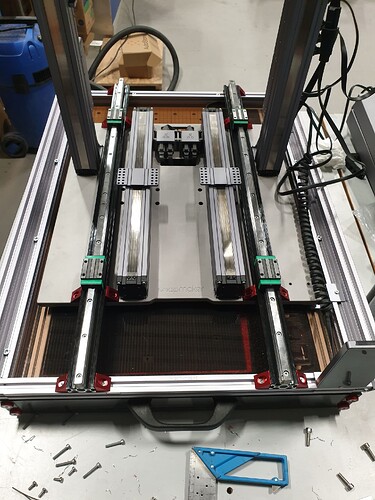

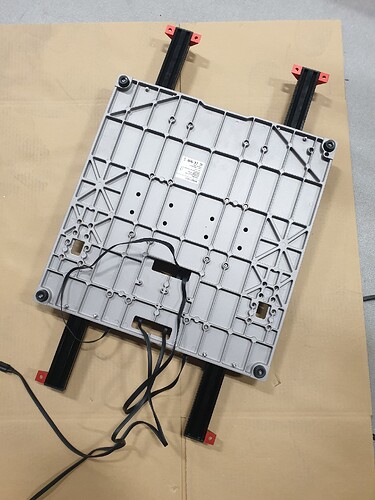

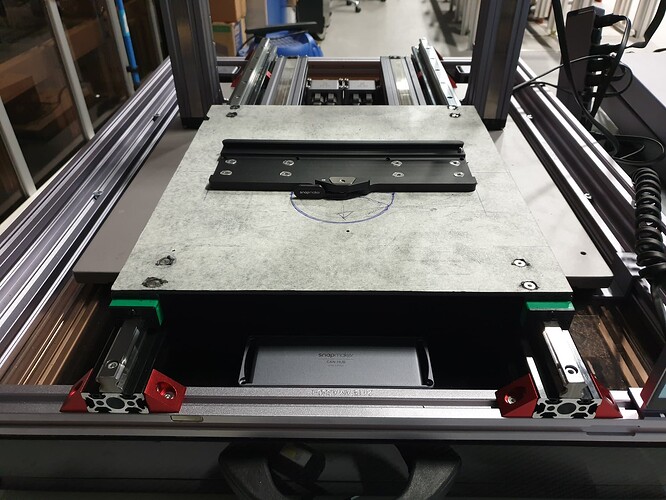

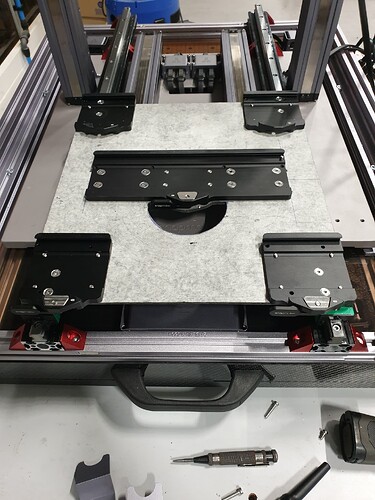

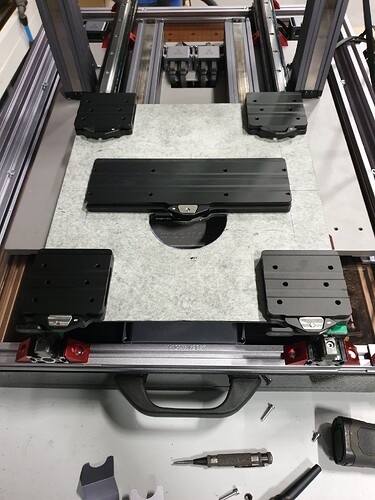

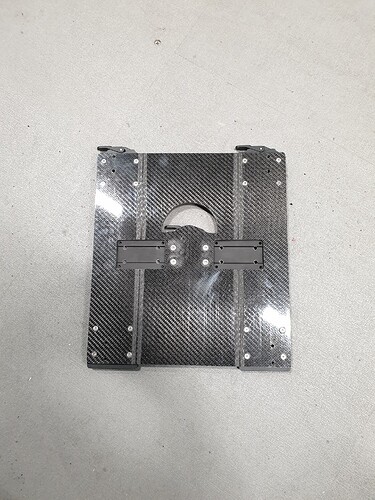

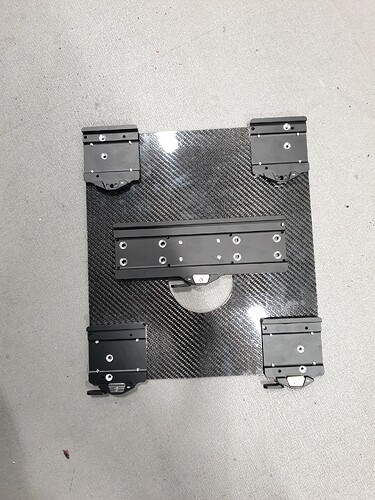

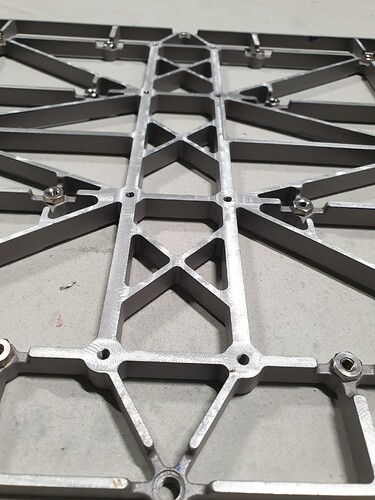

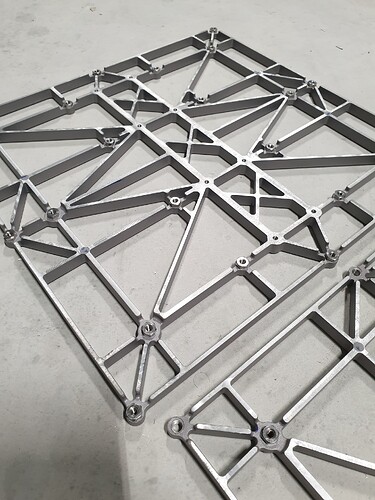

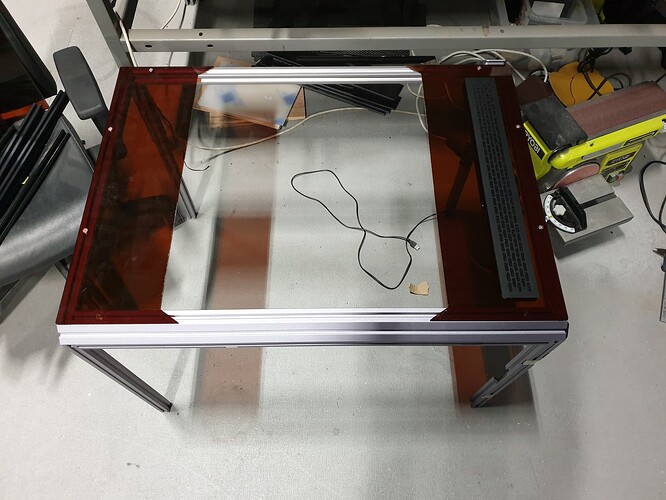

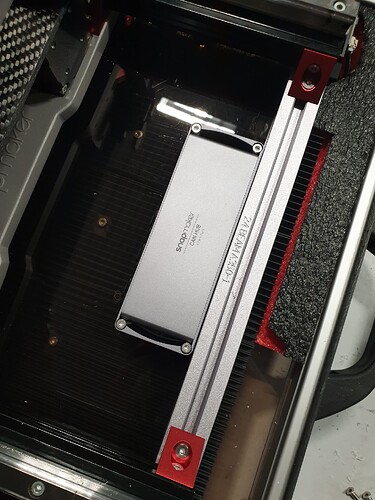

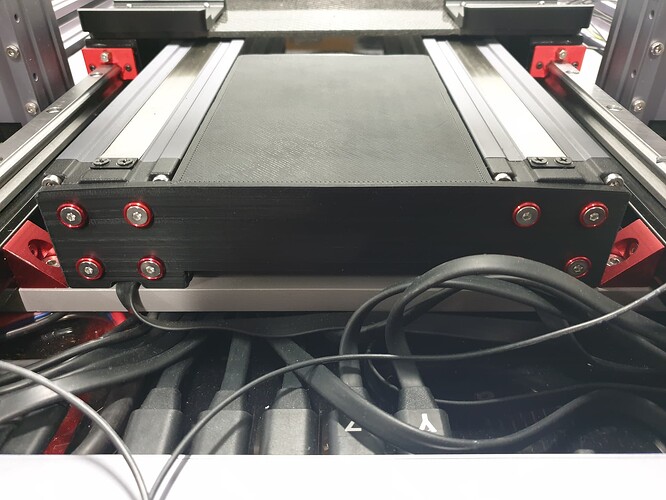

With the E stop looking a lot neater the next task was to figure out what I was going to do with the other beds when not in use. Again the enclosure was a near perfect single unit apart from the left over beds like the waste board and laser bed etc. So I decided to make a drawer that would fit under the enclosure to keep the spares in:

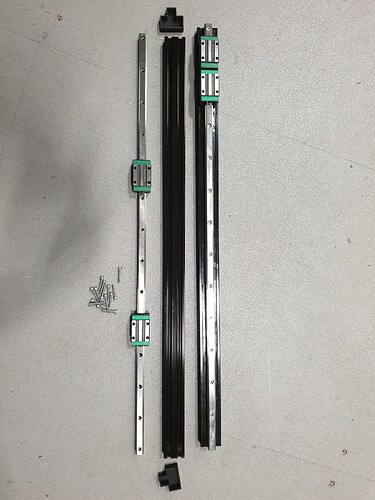

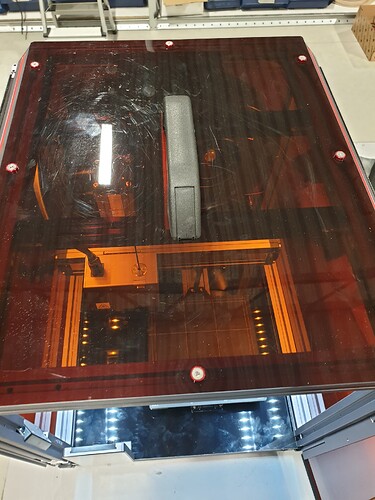

As you can see from the above pictures I also added mounting points for a strap to again make it easier to carry, and some red racing stripes to make it print faster. I also bought a second A350 from Ebay which ended up being free! the seller was some kind of fraud and got kicked off Ebay and I got my money refunded and got to keep the printer! it also turned out to be the A350T version so I plan to steal the new quieter linear rails from it in the future. For now, its purpose is to print parts for the original A350.

That is all for today, I will upload more progress tomorrow!