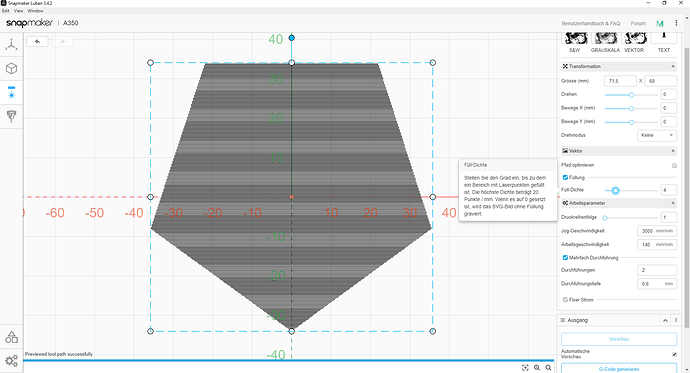

Danke, kannst Du mir ein Screenshot senden, damit ich sehe, wo ich das einstellen muss? info@robertschmid.ch

Sorry.

Wo ich das einstellen kann.

Herzlichen Dank.

Gerade habe ich gesehen, dass ich erst die Version 2.7.1 installiert habe, dort hat das nämlich nicht richtig funktioniert. Mit der Version 3.4.2 funktioniert es gut.

Herzliche Grüsse

Robert

Please, center the camera capture, that we can zoom normal like in 3D printing.

Bring back being able to simply click and then drag a model to where we want it on the print bed rather than having to us x / z arrows to move it - this is necessarily pedantic and quite annoying not to mention a waste of time.

Can I suggest a completely different format for this where there is FAQ search for ‘Can I do X’ and when the answer is no you get to upvote it so the Dev team can clearly focus on what users want. The point of the FAQ section is to cut down on forum posts adding noisy data to the forums (whos search functionality is quite poor) and to allow for specific feature requests to be voted on. Also publishing a dev release schedule so we know when versions are being released and assigning 20% of that version to adding in specific requested features or showing how the work on underlying sub-systems is linked to the progression of certain feature requests.

We do plan on making a dev release schedule post here on the forum. Thank you for your advice.

Glad to hear it, what is the release cadence that you are planning for Luban?

I actually think increasing matrix size is pointless, if auto calibration doesn’t work well anyway?

Roughly we release a firmware update every month and a software update every 2-3 weeks. The schedule might fluctuate sometimes but it is a good approximation.

…and wake up @Rainie a day per month to do some work

Haha since some of us still WFH now, I am not so sure if that is effective

@JKC20 she is getting old, just let her rest. (one day she is going to beat the crap out of me)

I would like to see the Snapmaker team implement the persistence of settings in Luban software. It could possibly be achieved either by a keep settings button or by just keeping the settings used previously until they are specifically changed deliberately. It would make processing a batch of similar situations far more efficient rather than having to enter the settings for every iteration of a similar process. Thank you!

You can already save your custom profile in Luban 3.5.0. The settings are just buried under Customize.

Once you save your custom profile, you can upload it next time you run Luban and you will get back your settings.

We are working on addressing some known bugs in Luban 3.5.0. The bugs only affect the interface not the actual use.

I remembered that I did not finish this conversation with you JKC20. My apologies. The persistence of settings issue remains for me when using both CNC and Laser etching. I believe that it is correct to say that the settings which are saved with the customised printer profile you have illustrated, are only available for 3D printing. Unless I have missed it, there does not appear to be any place to customise the profile in either the CNC or the laser segments of Luban.

Some way to set the values and keep them set until explicitly changing them would be my ideal.

Another thing that would help is to make the set origin value readable. This would ensure that an origin was where it was supposed to be for subsequent iterations of the process, even some weeks later.

I guess that it would require the software to readout an absolute Cartesian coordinate location beginning from its home position and it would be one that would never change. The changes in values would be the response to movement of the modules along the ‘X’ ‘Y’ & ‘Z’ rails.

Additionally it would be great to have an absolute value in linear measurement for the focussing of the Laser beam on the ‘Z’ axis.

My final request would be to have the calculations done by the machine when setting up CNC work. I would like the dimensions of the mill bit to be subtracted from the dimensions of the workpiece so that e.g. a 40mm cutout could still be specified in Luban as 40mm; not 37mm (as near to 3.187mm as is allowed) with an endmill dimension of 3.187mm.

It reminds me to ask for better dimension specification resolution too. The jog resolution is 0.1mm and the Luban software only permits 0.1mm to be entered. The ability to specify closer tolerances, when CNC milling, would be very helpful. (it would go some way to a fix for being unable to specify mill bit sizes in better than 1/10th of a millimetre resolution) The jog resolution of say… 2 decimal places would be great and entering values to an accuracy of two decimal places would be a huge improvement.

When uploading a SVG or DXF file to laser engrave, you should include different colours to set different parameters. for example a black line can bet set with one speed and power while a red line can be set with a different speed and power. This is how commercial laser engravers operate.

If i want to 3d print and have already a generated gcode, i load it to the workspace.

Here i have everytime to scroll far out to see the object and not just the cross of the coordinates (A350).