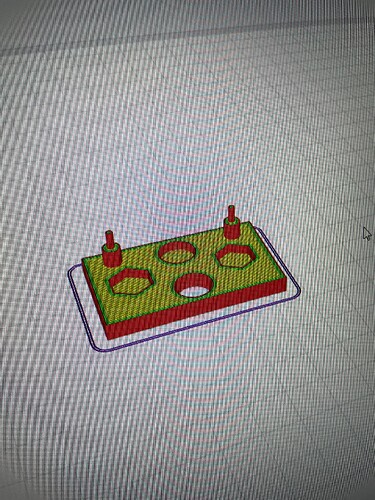

I use a Snapmaker A350t. In the past, the 50 mm solid drawings I drew were printed at exactly 50 mm size. As time went on, I continued printing parts that didn’t require measurements. I bought Iglidur i190 filament. I was aiming to print professional parts with it. However, the nozzle clogged. So I replaced the nozzle. Since I was starting out, I decided to print a measured part. However, the 50mm solid model printed at 49.8mm. As a mechatronics engineer, I couldn’t stand this. ![]()

I proceeded by eliminating the possibilities.

-

I replaced the hot end entirely with a new one.

-

I removed the two rails that move the hot plate and reassembled them in their home position.

-

I updated the firmware and re-did the entire setup.

-

I deleted and reinstalled the Luban program.

-

I chose a time cooler than 30°C to avoid the summer heat.

The print piece shrinks by 0.2 mm in all directions. However, the holes are the exact size. Therefore, I cannot enter the shrinkage ratio. Why am I printing at 49.79 mm, while the pieces I made before were 49.99 mm?

I used two different brands of filament. I bought both filaments, opened them from their vacuum bags, and printed directly without drying them. However, I’d never drying before. The only possibility I haven’t tried is drying.

If anyone wants to help, I can send you photos of my experiments.