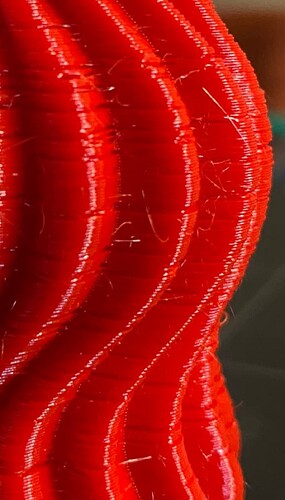

Hello everyone! I’m new to 3D printing and need some help. After bed leveling I’ve followed a tutorial on extrusion calibration. As you can see in the title of this topic, I’m using a brand new PETG filament from Snapmaker. In addition to this, I’ve put it in the SnapDryer and the humidity is around 15%. Unfortunatly I can’t get a decent print quality, having issues on the outer layers and in the infill pattern. I’ve tried to print some temperature tower test files, but completely useless since after the first level, it beak up.

Please can you tell me how you set up your machine and if there is a protocol and/or a page where I can follow a step-by-step to get those stunning results I’ve seen from other users?

Please help, thank you!

You can find below some pictures.

What are the temps you are printing at?

230°C for the nozzle and 70°C for the table, 25mm/s speed

I think there’s two problems there. Under extrusion as well as stringing.

Both could be caused by too low a temp, preventing the filament from melting and flowing properly.

Bump your temp up by 5 to 7 degrees and do a test print. Say 235 to 237 on the head, depending on where you are, your ambient air temps and if you have an enclosure.

Unfortunately I have no enclosure and the room temp is not that high at the moment (around 19°C). I’ll definitively check the temperature increase if it’s the right solution for my issues. In any case thank you for your helpful suggestions! ![]()

Have you dehydrated the filament? To me your issues look like typical moist filament problems. PETG is notorious for being hygroscopic, and I have found that Snapmaker’s PETG is additionally one of the worst for it. Of the 3 rolls of SM PETG that I have used, all 3 needed significant drying to make them even remotely usable, and even then they still had a LOT of moisture related problems. I have had no such issues from brands such as Overture and Polymaker, and I have printed more PETG from the two of them than all other brands and filament types combined.

Additionally, I print PETG at temps of 245C/80C and speeds not to exceed 40mm/s, but you need to be cognizant of your hotend if you are using a stock one; the PTFE liner in the hotend will eventually start to degrade at what are typical PETG print temps. More on that here: Hot End Clogs - The How & Why

Consider e-steps, flow, linear advance, and retraction calibrations a requirement for PETG to reduce stringing and surface artifacts; it loves to highlight and exaggerate any deficiencies in your tuning. It’s a very unforgiving filament, but once it is dialed-in, it can be wonderful.

Looks like he’s dried it.

Are you sure your spool is spinning free enough so the extruder can feed correctly?

There are so many gaps in your print, maybe try without the dryer?

Extrusion looks good, I’ve also performed an extrusion calibration with the dryer already installed

This are the gaps I am talking about:

Please double check your feeding path and if the filament on the spool gots not tangled.

Printing another vase without dryer would be useful.

Regarding the feeding path I’m 100% sure there are no tangles between the print head and the snapdryer. Since is PETG I would not put it outside and run another print since it’s winter now and humidity is really high in south of Italy (even if it’s cold).

If it’s dry, there is no problem for let’s say, few days printing.

I print with way more wet filament, this are other issues like I can see here.

I’ve run at least 3/4 cycles of dehydration in the snapdryer with fresh silica inside. Now the LCD shows a RH of 10%, which should be ok for printing PETG. So far the nozzle doesn’t seem clogged, since I’ve run several times the load/unload command and I’ve also performed the extrusion calibration test, to set the machine/software with the proper value.

Additionally I’m printing now with a temperature of 245/ at a speed of 25/30mm/s. Here some of the results: it seems that for some reason simple geometrical structure (like the 2cm cube) have less problems when printed with the above settings but, when it comes to some more complex shapes, everything return to be not precise as well as stringing and the grid infill is so messy that is not able to give stability to the objects.

I would check the nozzle for wear, maybe just go ahead and replace it, and when you do, take the hotend out to see if the PTFE liner is trashed, as I talked about here: Hot End Clogs - The How & Why. Otherwise, it may just be that the filament is unrecoverable, which has been known to be the case on occasion. One way to check would be to use a new roll of a different brand of filament, preferably a known high quality one like Overture or Polymaker. If the new roll prints fine, then the old one is junk at this point. Something else to keep in mind: the RH reported by the dryer is the RH of the air at the sensor, not the moisture content of the filament, so it can never be 100% trusted, it is really just a reference.

I’ve read your “Hot End Clogs” topic and I’ve found it really helpful but I’ve decided to give another try to my hot end. But after today, I think I’ll try another filament and if it doesn’t work, I’ll definitely change the hot end. Thank you Mxbrnr!

I was going to write the same. The filament is so tightly wound that there is really very little chance that the filament is going to give up its moisture to the surrounding dry air in a short time.

I plan to try an experiment: to dry the air with filament in a dryer box to a very low level and then seal it up and watch it for days to see how quickly the humidity in the box rises again as the moisture slowly comes out of the filament.

Doing that, keep in mind that RH is temperature dependent; 10% RH @ 55C is the same actual moisture content as 50% RH @ 25C, and vice versa. So if you start with a chamber at ~23C (typical room temperature) and 50%RH, then when the chamber has reached 55C and reads 10% RH, nothing has changed. And since most hygrometers used in consumer-grade products don’t read below 10%, you won’t really be able to know if it’s getting any drier or not.