Hello everyone,

I’m sharing the configuration changes I made for my Snapmaker 2.0.

I changed the startup G-code because the nozzle wiping on the bed causes issues with certain filaments, and the “if 1=1; then reconfig Z0” messes up my calibration.

Here is the corrected G-code (Note: this only works with a module that has a single extruder):

; Update: 20250313

; Printer : [printer_preset]

; Profile : [print_preset]

; Plate : [plate_name]

T[initial_extruder]

M140 S{first_layer_bed_temperature[initial_extruder]}

; you can clean the nozzle

M104 S165

M204 S100

G28

M190 R{first_layer_bed_temperature[initial_extruder]}

M83

;{if max(hot_plate_temp_initial_layer[initial_extruder], hot_plate_temp;[initial_extruder]) >= 90}

;G0 Z0.06

;G92 Z0 ;reset z

;{endif}

; flush initial nozzle

T[initial_extruder]

M104 S{nozzle_temperature_initial_layer[initial_extruder]}; common flush temp

G0 X-10 F3420.0

G0 Y-10 F3420.0

G0 Z1.6 F960.0

M109 S{nozzle_temperature_initial_layer[initial_extruder]} C2 W1

G1 Z1 F200

G1 E20 F100

G92 E0

M106 S{min(255, (fan_max_speed[(initial_extruder % 2 == 0 ? min(initial_extruder + initial_extruder, 63) : max(initial_extruder - (1-initial_extruder), 0))] + 10) * 2.55)}

G0 X10 F3420.0

G0 Y10 F3420.0

G0 Z0.3 F960.0

G1 E-{retraction_length[initial_extruder]} F200

G92 E0

; ready [plate_name]

I have put comment on if before to correct it ![]()

Additionally, I’m sharing my “optimal” and “fine” configurations, which still need optimization but correct an excessively high speed and, more importantly, a sudden acceleration that causes errors between layers.

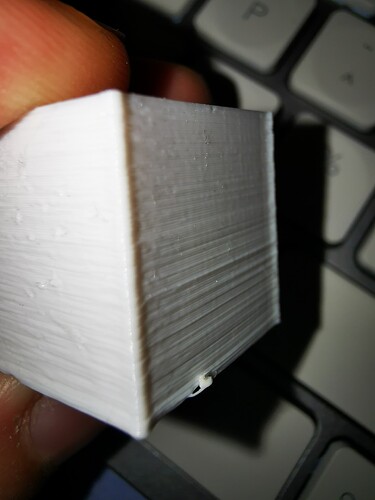

If you can help me improve, I still have issues like this that are frustrating me: (perhaps it is the PETG filament)

Printer presets.zip (2.2 KB)

Thank you