Are those cold temperatures?

What is your M851 reading. (in the M503 command)

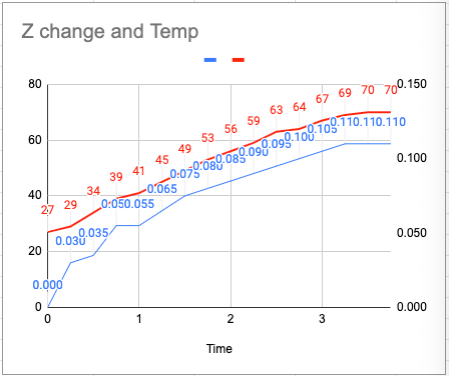

Here’s a plot of Z offset vs Temperature. The x axis is minutes.

I positioned the dial indicator in the middle of the bed.

The M851 reading is Z1.00

This was me setting the temperature to 65 and then running auto, I thought it was holding temperature as Luban was showing 60. Actually it was dropping but it didn’t update the temp display until auto calibration was completed.

Can I execute auto-calibration via the command line and have it hold temperature?

I think as soon as you do a calibrate either manual or auto it shuts off the heat.

This has been my experience as well.

Hi, I am new to 3D printing. I am having some issues in the calibration where some points are further from the nozzle, especially left and center. Also, the nozzle has been digging into the corner (0,0) if I am to follow the instructions of the manual closely.

I was advised by someone of the same methods you were demonstrating. I downloaded and updated the firmwares of Luban and the printer (A150). However I did not lower the printing module to the lower half as I thought it is only meant for the larger printers, ie A250 and A350. So do I also change the position of my module by moving it down to the lower half? Do I let it stay that way when I am doing any print?

Anyway, I have tried to calibrate after updating the firmware and the issue of calibration is about the same. Alas I continued with trying some prints. But there is a new issue of nozzle stuck at last print location, resulting a hole in the job. A message appeared indicating a lost in connection when job is done at 100%.

The module is lower to the lower half solely for the purposes of ensuring the module is level and giving you access to the screw on the back that holds the inductive sensor in place, so it should be valid for any of the systems. That sensor is what tells the machine that it is close to the build plate and to rise up a little.

Do not under any circumstance attempt to operate the machine with the module in this position. I repeat do not attempt to operate the machine with the module attached solely on the bottom of the mount point. You will absolutely cause damage to your machine.

Once you’ve adjusted your sensor height, move the module back to the proper location.

Alright. I got you now. Thank you very much.

Could post the info of every point during the calibration process? We can see three probing tests in every point and find if any significant changes in values.

I think they probably take an average of the 3 probed values and then they have to subtract the Z offset. In a normal Auto Scan, that Z offset is what you get when you do the last step in Auto Calibrate and measure it. That value is shown on the console at the end of Auto Calibrate.

My question is, what Z offset do they subtract when doing the “Fast Auto Calibrate” @parachvte?

The last one measured?

I probably should have posted this in this thread;

Hello everyone, about this leveling problem, I suppose it is because of the bed wich’s metallic structure is changing shape due to heating (classic dilatation/retractation with metal), one question thought, if I only print PLA, the bed doesn’t need to be heated, can you disable heating? so that there wont be issues about level calibration… just wondering

It’s normally recommended to heat the bed for PLA as it helps it to stick. Then when it cools it also helps it to break free.

I see… thank you for your anwer

More observations, In trying to make sure I’m getting an accurate reading with my dial indicator and that it is in sync with the nozzle z distance I discovered some movement that isn’t the bed surface, it’s the play and backlash in the X & Z axes.

I’ll tell it to go down to Z.1 (the thickness of the setup card) and it goes down to Z.15, I tell it to move 19mm in X and it goes down to Z.1, move back 19mm and it moves away from Z.1 and then back to Z.1. So it seems to me that movement in the X-axis is causing slight movement in the Z direction. I don’t know if that is because the stepper motor is applying a torque which results in the Z movement or if the inaccuracy in the X-axis rails are causing the z movement.

If after it is commanded to go to Z.1 I push down on the head with a slight force then it seems to take up that .05 play and it will settle at the Z.1 on the dial indicator. Taking up that play or slack doesn’t make the slight movement in Z when moving the X axis. Maybe what I’m seeing is the leveling in action. I need to understand how the leveling is implemented. I’m talking about .02 to .03 of Z travel over a distance of 20mm in X.

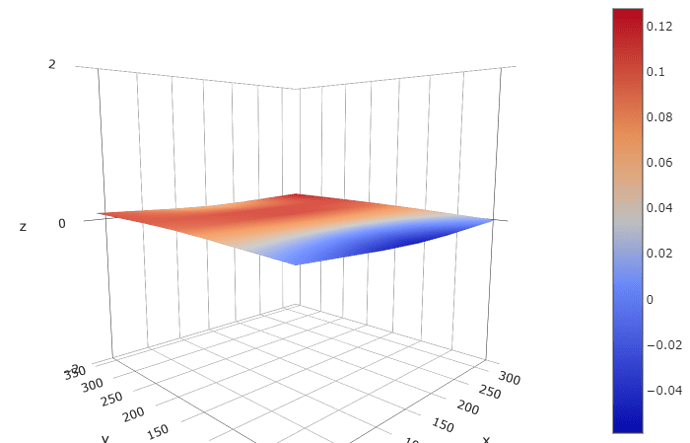

Well most of my Sunday was spent doing this. Manual leveling and a trick I thought up after getting frustrated with the flatness of my bed or the lack there of. Also did an auto calibration after I achieved a flat bed the manual way but the lack of being able to probe the bed at temperature and using only a nine point mesh really hinders the process.On the latest v1.7.0 firmware as well.

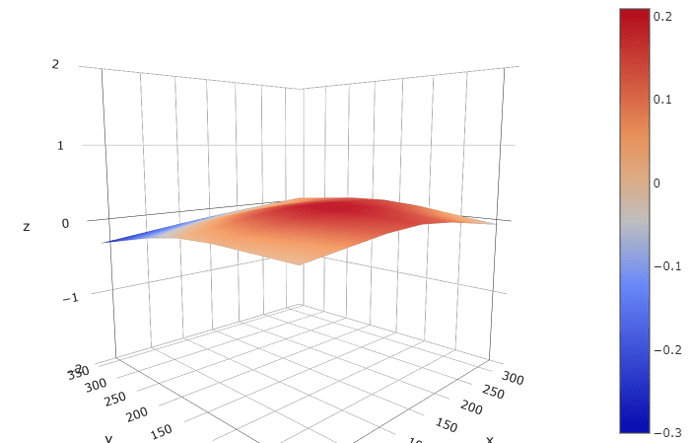

First pic above is stock and my process continued until I reached flatness

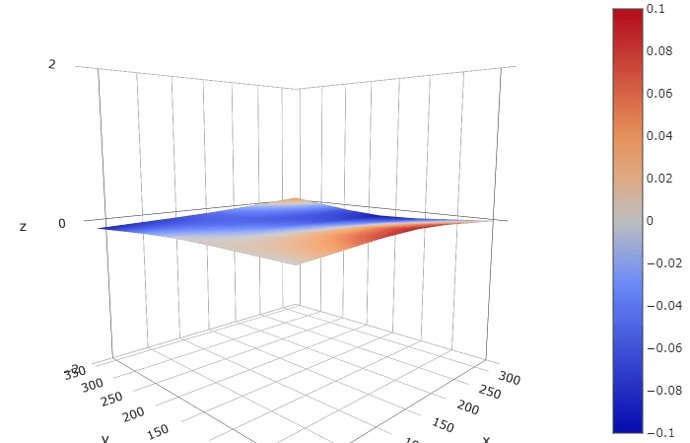

This is an automatic level after the manual level was flat and just as it would be performed (cold bed).

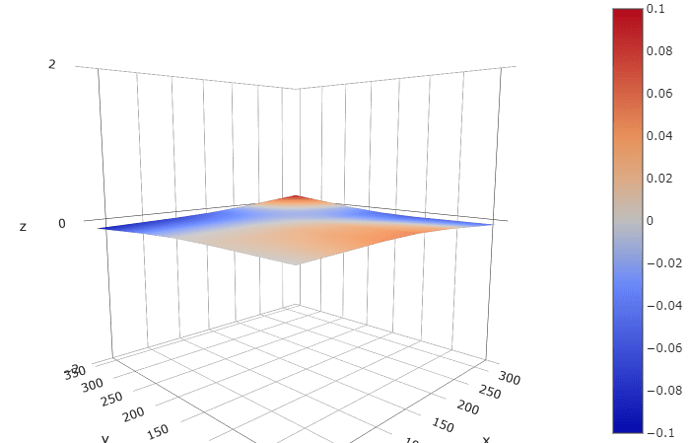

And this is an auto level after manually heating the bed to 70C and then running a level.

Print on manually leveled stock steel sheet

Print on auto leveled bed (same gcode for all prints)

Had to babysit the entire layer and adjust the Z offset as best as I could.

Currently switched to the glass bed and returned to manual leveling.

Is this data from M420V output?

What are you doing to test if the level is good?

Are you manually tweaking matrix points?

Yes that is the M420 V data rendered in Octoprint. I removed the bed heater and placed silicone o-rings on the screws between the heater plate and bed mounting plate. That allowed for some adjustability by selectively tightening or loosening the mounting screws for the heater. A tedious process to be sure and one that I hope a firmware update (or a flat replacement bed) will alleviate the need to perform.

I am still waiting on a reply from support for my damaged bed now that we know there were several bugs in the firmware. @Rainie