Image first

Because FDM printer’s nozzle travels across an open space and move between different points, and the melting filament may get oozed and then solidifies and sticks to the module like shown in the picture above. We call this issue the 3D printing stringings.

In theory, your nozzle should not deposit plastic as it travels through open air (otherwise known as a travel move). However, molten plastic will often leak onto parts where it shouldn’t, leaving your prints with what looks like “whiskers”.

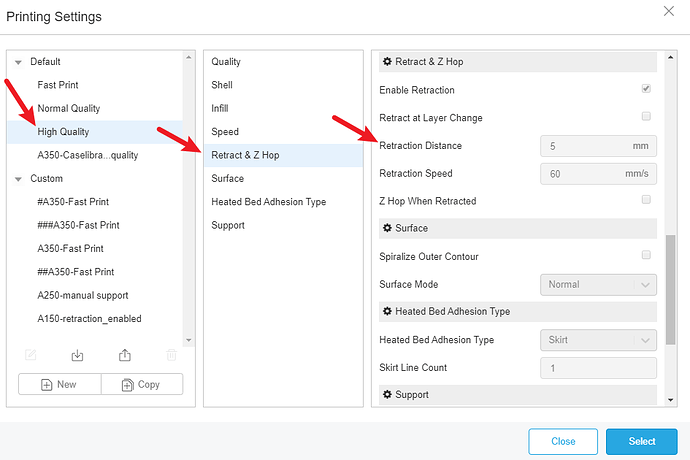

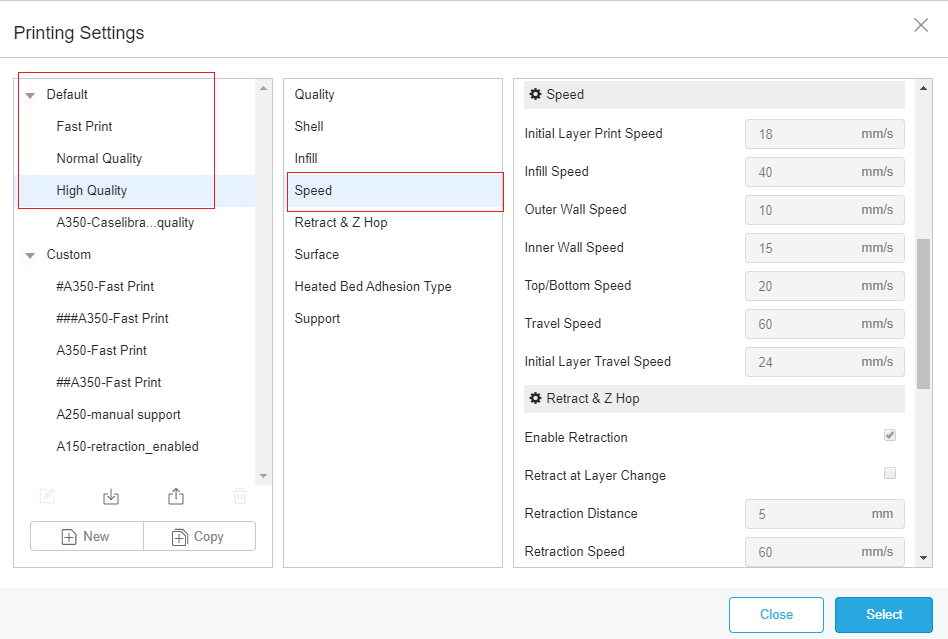

In Snapmaker Luban, users can increase the retraction feature. Enabling retraction means that, where the extruder has to cross an empty space, the filament will be pulled back – just a little bit – by the feeder. This prevents the molten plastic from trailing behind as the printer head moves because the “pulling back” action serves as a countermeasure against oozing. Once the extruder has arrived at the next location, the filament is pushed back out, and printing resumes from the nozzle again.

Retraction Distance

Retraction distance is crucial to the retraction settings, as it determines how far the filament travels. Normally, if the nozzle retracts further, it means that the 3D printing stringing is less likely to happen.

The default retraction distance in Snapmaker Luban is 5mm, and users can change it in a new printing profile.

Retraction Speed

The retraction speed determines how quickly the filament is retracted. A faster retraction speed suggests that 3D printer stringing is less likely to occur because the filament is pulled back fast enough before it starts oozing. However, when the retraction speed is too fast, it may cause the filament to disconnect with the other portion inside the nozzle. Worse, a quick movement of the drive gear may grind the molten plastic and jam the nozzle or create areas where the filament is not deposited.

Different retraction settings can significantly increase or decrease blobs (Source: Domoticx)

Set the Right Temperature

The high temperature will cause the filament to become more liquefied and is more like to drip from the nozzle even you have adjusted the retraction settings.

An ideal temperature depends on the printing material and other printing settings. However, it’s generally recommended to lower the temperature once you notice stringing. You can try reducing the nozzle temperature by 5 to 10 °C increments, but never reduce the temperature below the manufacturer’s minimum specifications.

A model like a temperature bridge can help users to find out the best printing temperature.

Temperature Bridge

Adjust the Print Speed

Travelling speed can also affect 3D printing stringings. If the travelling speed is too low, the nozzle takes too long to move from one point to another point, and the melted filament will drop down to the printed model.

Generally, a speed of 190 to 200 mm/s will work fine with most printing materials. Users can refer to the recommended printing settings in Snapmaker Luban.

Thoroughly Clean the Nozzle Before Printing

When you use a printer for a long time, especially with a single type of printing material like PETG, the filament can leave a thin layer of residue in the nozzle. This thin layer can cause 3D printer stringing as filament strands will try to stick to the surface of your printed part.

Dry your filament

All FDM 3D printing filaments are hygroscopic. That’s a fancy way of saying that the material likes to absorb moisture.

Please keep the filament free of moisture.