Thank you this is very helpful. I was not keen of overwriting my FW given all the new update from snapmaker for the new laser, cnc, bracing and quick change kits. I will however, still continue my full read of this thread as there are a lot of great information in there. Plus I would not want to complain and be blamed of TL;DR

Cheers

I have lightburn working and have done a few prints but it looks like lightburn is not setting laser power correctly. It seems to be only one power level even though I have it set different, also it is not cutting like it should at 100% and 3 passes should cut through 3mm. I know my laser is ok did the same test using luban had no issue cutting. What did I miss with lightburn. I have the latest firmware for my SM2 and latest version of lightburn. I have tried the latest version of the modified controller with the correct version of snapmake firmware. Same result plug into SM2 with serial cable.

What S-Value do you have set in Lightburn? The machine shouldn’t care what program created the gcode, as long as it’s the same settings.

I have went through the guide, had problems get the header code correct, figure that out, did a simple box as a test it made the box but should of cut it out. And on your comment I agree it is weird and drive me nuts right now.

Make sure in your later options to select constant power mode as well, so it doesn’t lower power during deceleration moves. You can also try exporting the gcode with the save gcode button, then feed it back in with run gcode. This will let you look at the file before running it. Also, mind uploading the nc file?

sure here is the test file, something interest just happen I closed down Light burn, opened back up, open the test file again, saved it to my usb, ran it on SM2, Lightburn is set for 3 pass, but when it ran it did 3 pass 3x.

test.nc (820 Bytes)

this is my other file I have been testing:

Monster_Court.nc (546.5 KB)

Think I noticed the problem, you’re in mm/sec and you should be working in mm/min. You’re running absolutely too fast. In your test file you have your feedrate set to 30000mm/min.

; Cut @ 500 mm/sec, 100% power < 500mm/sec * 60 = 30000mm/min

M8

M5

G0 X20Y20

G0 Z0

; Layer C00 Pass 1 of 3

M3

G1 Y60S255F30000 < F30000 == 30000mm/min

On the menu bar, go to Edit > Settings to bring up Lightburn settings. Then swap over to mm/min.

looks like that was the issue, going to do a few more test to full confirm. I don’t remember changing that to mm/sec though.

That’s the default setting in Lightburn, unless you changed it, it was always that.

Thank you for the help. After reading information on constant power I had a feeling it was a speed issue but didn’t think looking for a setting. Things are printing right now. Even on the first test the head moved as expected not like it did previously. Thanks again.

Glad it was a relatively easy fix.

The is the only way to get this to work is to install old firmware? or is there a version that still gives full control?

Changes were merged, so the latest firmware works fine.  No need for custom firmware anymore.

No need for custom firmware anymore.

1 Like

Hi - I got my A350 connected to Lightburn without any issues. However I cannot the10W laser to output enough power to make cuts. It goes about 2/3rds of the way through on an 3mm piece of wood but doesnt make full cuts. I have the settings at 180mm/min and 100% power.

I suspect the settings in Lightburn are such that the power when set to 100% is not really 100% of the actual laser.

Anyone know how to set this for the 10W laser?

Thanks!

PS the same files cut with no issue in Luban so it’s not a hardware problem.

Are the settings correct?

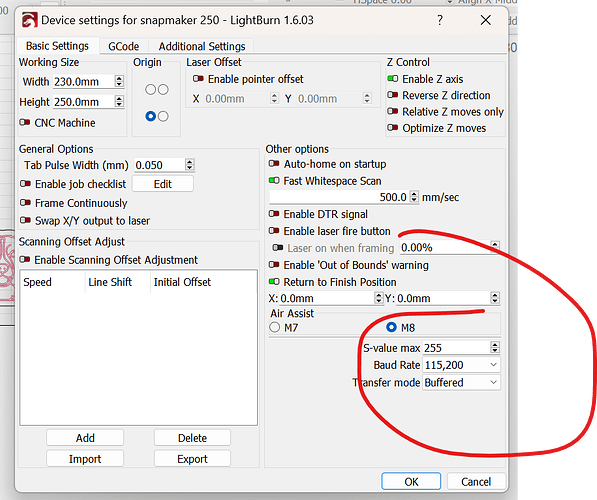

What is the max S-value max? (edit=>device settings). It must be 255.

Yes I believe it is 255. I will post a pic of the settings.

The firmware version of the A350 is V1.20.3_20240716

The version of Lightburn is 1.7.01

I didnt put any Gcode headers or footers into Lightburn. I use the front panel to send the head to the right job origin location (this is the location that does great cuts in Luban) and set the work to start from there via Lightburn.

Here are the line cut settings in Lightburn and Luban

The Luben does clean cuts right through the 3mm basswood. Lightburn gets about 50% through, maybe less in some areas.

Could you please upload the gcode file generated by Luban and Lightburn. If the S-Value is set to 255 as it should, and you’ve set 100% power, then the gcode should be indifferent to the machine. There may be something else at play.

![]()