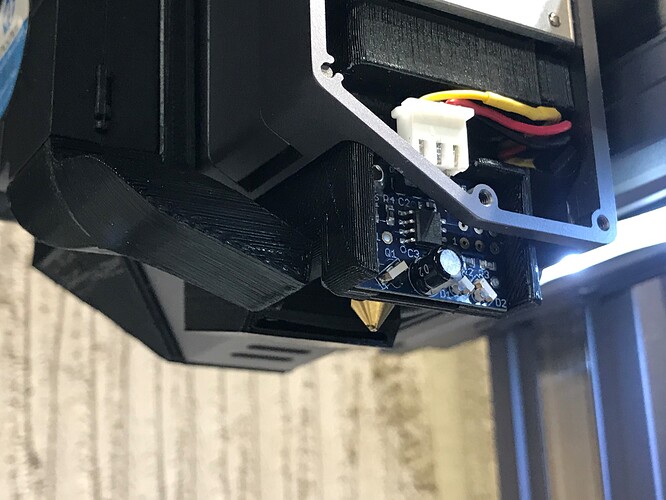

I wanted an alternative sensor that would work on glass and if possible would fit within the main body of the print head. After some research I found an IR sensor that gets good reviews for accuracy and is small. It is 3.3V or 5V and logic high when triggering so I knew there would be some wiring issues but it’s small enough to fit on the right of the nozzle replacing the existing sensor and the right side fan duct. I think the right side fan duct doesn’t work well ( its removed in the new head) and I also use an external front fan. So I redesigned the blower fan box and a combined sensor mount and hotend fan box and a cable to wire it all up. I took 3.3v from the marked pad on the print head circuit board and it connects to the existing sensor connector. The wiring cable also contains a transistor to switch the sensor trigger to pull down the input on the print head board and a couple of resistors, one to make sure the sensor has 3.3v on it’s output to initiate the correct operational mode and another for the transistor.

The sensor is a direct replacement for the stock one and I can level on glass using the existing handset process and probe the bed at will.

Accuracy seems way better than the old sensor with or without FiFix type attachment, on 30 G30 probles only 1 varied by 0.01mm.

Nothing here is destructive so it can all be taken out and you can go back to the stock print head though I guess it will invalidate any guarantee!

I can share part design and a wiring diagram with a bit more information if people are interested. This was built for the Snapmaker 2 original print head, not the current one though I think it should work fine in either.

This is the sensor I used:

I bought it from Ooznest in the UK who I have found to be very efficient.